1

Split Heavy Applications

When calculations show >4 tons/ha needed, don't apply it all at once. Split the application: 50% in fall (incorporated deeply) and 50% in spring. This prevents localized over-liming and improves overall efficiency by 25-30%.

Why it works: Gives soil microbes time to adjust, prevents pH shock to existing crops, and allows you to fine-tune spring application based on fall results.

2

Combine with Organic Matter

Add compost or manure 2-4 weeks before lime application. Organic matter improves lime effectiveness by 20-30% through enhanced microbial activity and better nutrient release. The synergy is remarkable.

Application sequence: Organic matter first → Wait 2-4 weeks → Apply lime → Incorporate together in final tillage pass.

3

Monitor Post-Application

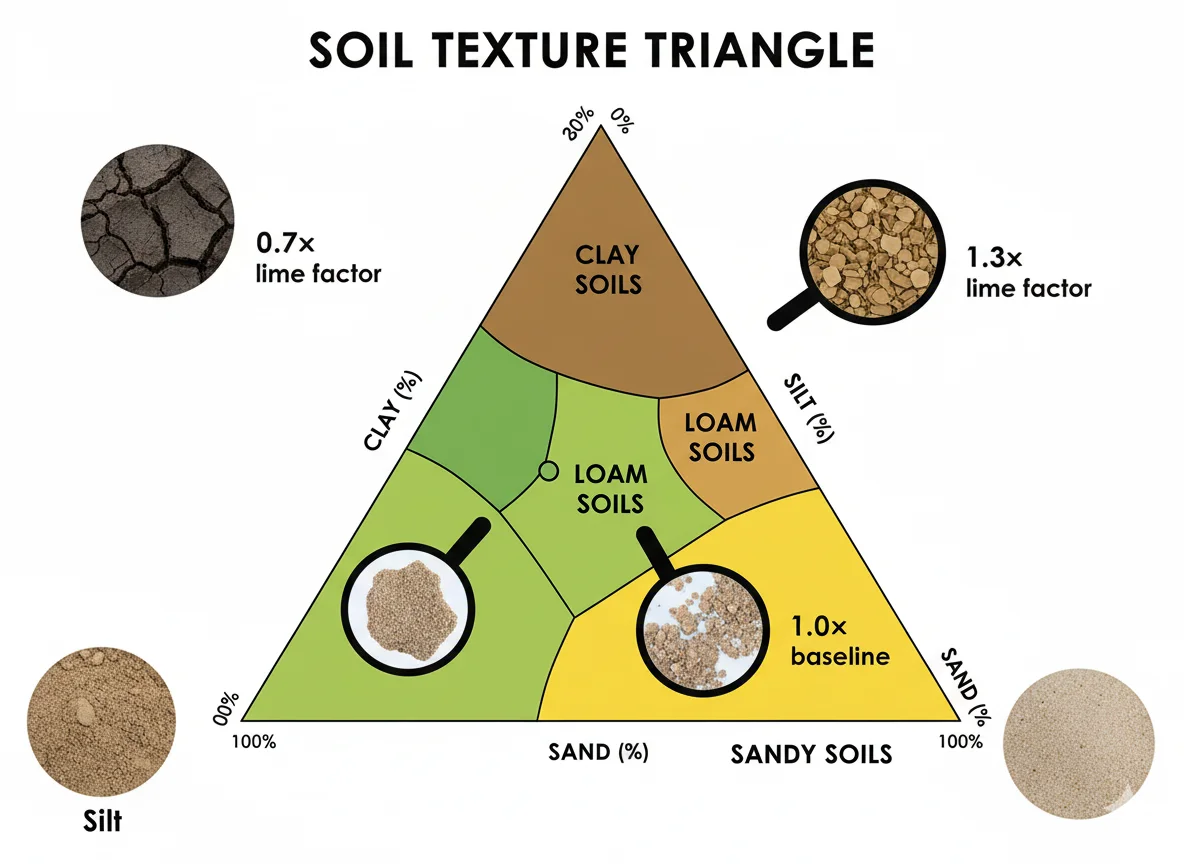

Don't apply and forget. Retest soil 6 months after application to verify pH change. Sandy soils react in 1-3 months, loams in 3-6 months, clays in 6-12 months. Track results to refine future applications.

Pro tracking: Keep a field journal with application dates, rates, weather conditions, and subsequent pH readings for pattern analysis.

4

⚗️

Particle Size Strategy

Mix 70% medium-grade (20-60 mesh) with 30% fine-grade (<60 mesh) lime. This combination gives you quick initial pH response from fine particles plus long-term stability from medium particles lasting 2-3 years.

Cost-benefit: Mixed grades cost 5-10% more but deliver 40% better performance over time compared to single-grade applications.

5

🎯

Use Pelletized for Precision

For no-till systems and precision agriculture, pelletized lime offers uniform particle size, zero dust, and better spreading accuracy. Worth the 15-20% price premium for large operations and GPS-guided application.

Best for: Variable-rate application, no-till farms, organic operations, areas with wind drift concerns, and precision ag systems.

6

🌡️

Time Your Application Right

Fall application is ideal—lime has all winter to react. Spring application works but requires 3-6 months before full effect. Avoid summer applications in hot, dry conditions when reaction rates are slowest.

Seasonal tip: Fall application + winter moisture + spring warmth = optimal pH correction timing for most crops.

7

💧

Manage Irrigation Salinity

If using groundwater irrigation with high bicarbonates (HCO₃ > 3 meq/L), your effective lime requirement may be 15-25% lower. The irrigation water itself acts as a pH buffer. Test irrigation water annually.

Water test: Include pH, EC, SAR, and bicarbonate levels in annual irrigation water analysis for accurate amendment planning.

8

📍

Zone Your Fields

Don't treat entire fields uniformly. Use grid sampling (every 2-5 acres) to identify pH zones. Variable-rate application based on zones can save 20-40% on amendment costs while improving results.

ROI boost: GPS mapping + zone sampling costs $200-500 but typically saves $1,000+ on 20+ hectare fields through targeted application.

9

🔄

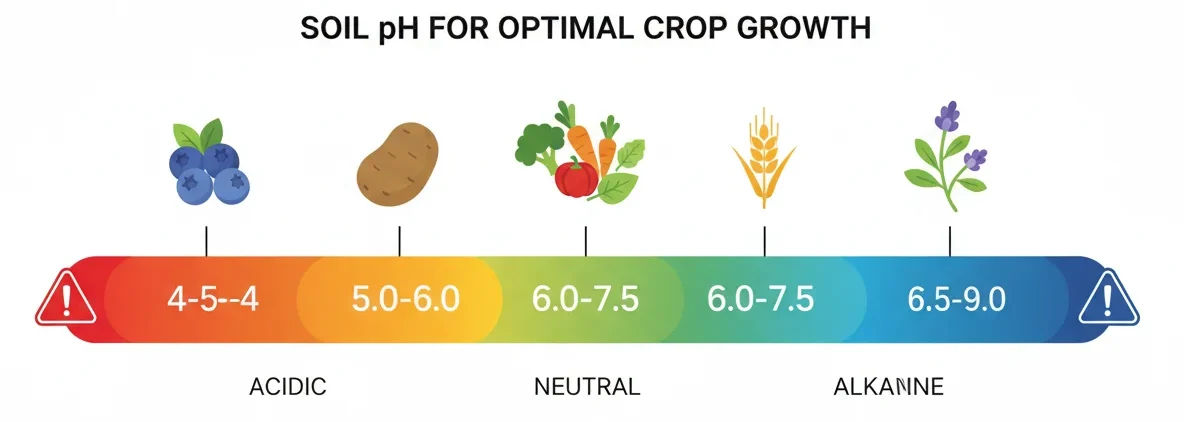

Consider Crop Rotation

Different crops have different pH preferences. Plan lime applications based on your rotation. Alfalfa (pH 6.5-7.5) needs more than soybeans (pH 6.0-7.0). Rotate high-pH crops after liming for best returns.

Smart rotation: Lime → Alfalfa → Corn → Soybeans maximizes lime investment across rotation cycle.

10

📱

Document Everything

Keep digital records of all applications: date, rate, product, weather, cost, and results. Use farm management software or spreadsheets. This data becomes invaluable for optimizing future decisions and proving ROI.

Data value: 3-5 years of records enable predictive modeling that can improve efficiency by 30-50% compared to reactive management.

11

Avoid Common Timing Mistakes

Never apply lime immediately before phosphorus fertilizer—wait 2-4 weeks. Don't lime right before planting acid-loving crops. Avoid liming frozen or snow-covered ground where runoff risk is high.

Spacing rule: Lime → 2-4 weeks → P fertilizer → 2 weeks → Planting. This sequence prevents nutrient tie-up and maximizes availability.

12

Calculate True Cost Per Unit

Don't just compare price per ton. Calculate effective cost based on purity and particle size. A $120/ton 95% purity lime beats $100/ton 80% purity when you factor in actual calcium carbonate content.

Formula: True Cost = (Price per ton ÷ Purity %) × 100. Compare true costs, not sticker prices, when sourcing amendments.