🔋 Battery Configuration

⚙️ System Configuration

📊 Load Configuration

| Appliance | Power(W) | Qty | Hrs/Day | kWh | Main | × |

|---|

Calculate precise battery backup duration based on load power, battery voltage, capacity, and inverter efficiency.

| Appliance | Power(W) | Qty | Hrs/Day | kWh | Main | × |

|---|

Learn how to calculate battery backup duration accurately with our comprehensive guide. Discover formulas, factors affecting runtime, and expert tips for sizing your backup power system correctly.

Ever wondered how long your battery backup will actually last during a power outage? You're not alone.

Here's the thing: Most people overestimate their battery backup time by 30-50%, leading to unexpected power failures when they need electricity most. Whether you're sizing a UPS for your home office, planning an off-grid solar system, or calculating emergency backup for critical equipment, knowing the exact runtime is crucial.

The battery backup duration calculator removes the guesswork. It considers battery capacity, load consumption, system efficiency, depth of discharge, and real-world losses that manufacturers often overlook. In this guide, you'll discover the exact formulas professionals use, understand why your actual backup time differs from theoretical calculations, and learn how to optimize your system for maximum runtime.

Let's dive into the science of backup power calculations.

A battery backup duration calculator is a specialized tool that determines how long your battery bank will power your electrical loads before requiring a recharge. Unlike simple capacity calculations, a professional calculator accounts for multiple efficiency factors that significantly impact real-world performance.

The calculator considers:

This comprehensive approach gives you accurate backup time estimates rather than overly optimistic figures.

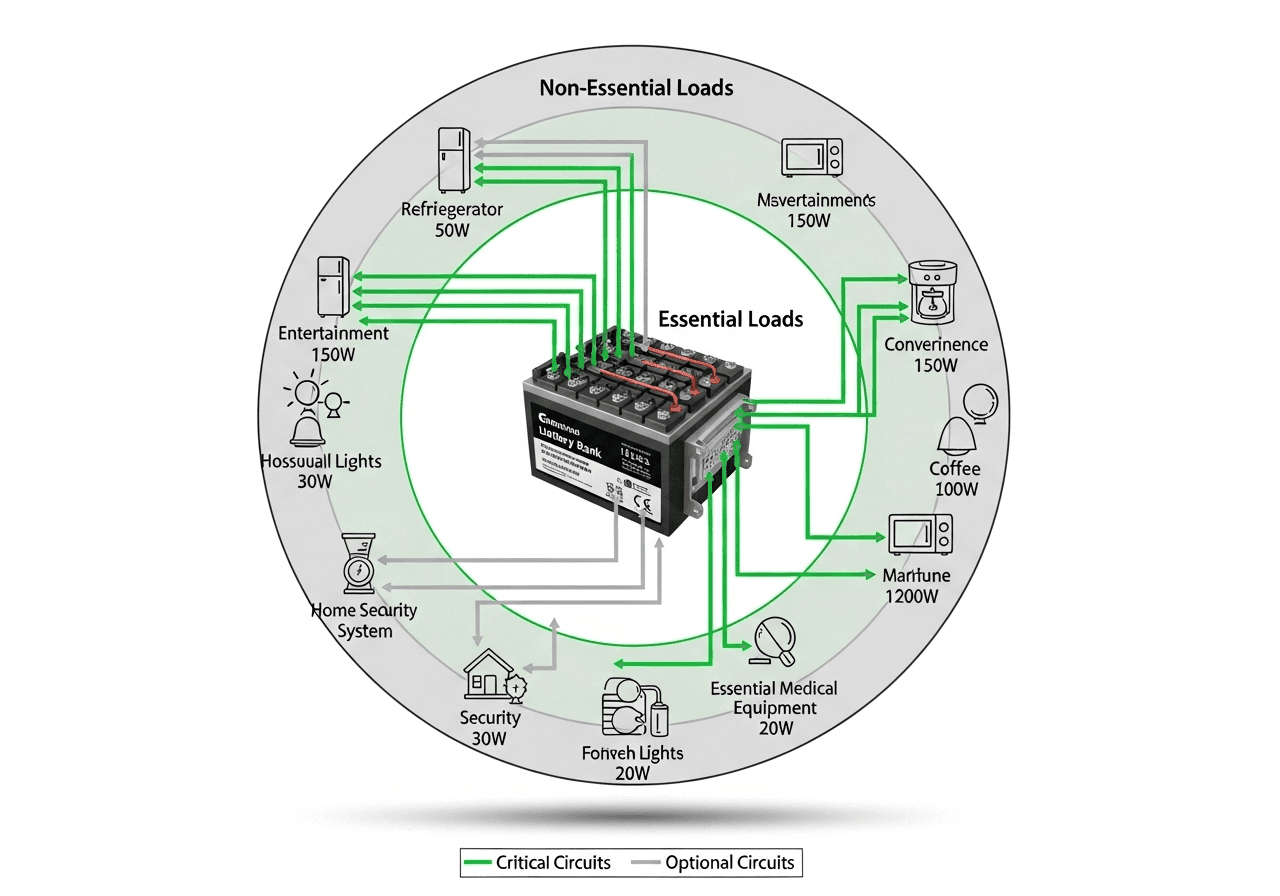

The consequences of miscalculating battery backup can be severe. Imagine your home security system failing mid-intrusion, your medical equipment shutting down during an outage, or your business losing hours of unsaved work because the UPS died prematurely.

Beyond emergency situations, accurate calculations save money. Oversizing your battery bank wastes thousands of dollars on unnecessary capacity. Undersizing leads to frequent deep discharges that destroy expensive batteries in months rather than years.

Professional installers report that properly sized systems last 2-3 times longer than incorrectly configured ones. The initial calculation determines your system's entire lifecycle performance and cost-effectiveness.

Battery capacity represents the total electrical charge stored in your battery bank. Manufacturers rate capacity in ampere-hours (Ah) at a specific voltage.

A 100Ah battery at 12V stores:

However, you cannot use all this energy. The depth of discharge (DoD) limits usable capacity to protect battery lifespan:

| Battery Type | Safe DoD | Cycle Life | Efficiency | Best Use Case | Relative Cost |

|---|---|---|---|---|---|

| Lead Acid (Flooded) | 50% | 500-800 | 85% | Budget backup systems | 1× |

| AGM | 60% | 1,000-1,500 | 90% | Maintenance-free backup | 1.5× |

| Gel | 50% | 700-1,200 | 88% | Deep cycle applications | 1.4× |

| Lithium-Ion (NMC) | 80% | 2,000-3,000 | 95% | High-performance systems | 3× |

| LiFePO4 (LFP) | 90% | 4,000-6,000 | 97% | Daily cycling, long-term | 3.5× |

| LTO | 95% | 10,000+ | 98% | Commercial, extreme use | 6× |

| Redox Flow | 90% | 20,000+ | 75% | Large-scale storage | 4× |

Notice how lithium-based batteries deliver significantly more usable energy from the same rated capacity. This explains their higher upfront cost but better value over the system's lifetime.

The master formula for battery backup duration accounts for all efficiency factors:

Backup Time (hours) = (Battery Capacity × Voltage × Number of Batteries × DoD × Battery Efficiency × Inverter Efficiency × System Efficiency × Temperature Factor) ÷ Load Power (W)

Let's break down each component:

The ampere-hour rating at the 20-hour discharge rate (standard specification).

Single battery voltage: 6V, 12V, 24V, or 48V. Multiple batteries can be configured in series (increases voltage), parallel (increases capacity), or series-parallel combinations.

Total batteries in your bank. Configuration matters:

Fraction of capacity you can safely use (0.5 = 50%, 0.9 = 90%).

Round-trip efficiency accounting for charge/discharge losses:

Typically 85-98% depending on quality and load percentage. Premium inverters maintain high efficiency across load ranges.

Accounts for cable losses, connection resistance, and distribution losses. Well-designed systems lose 5% or less.

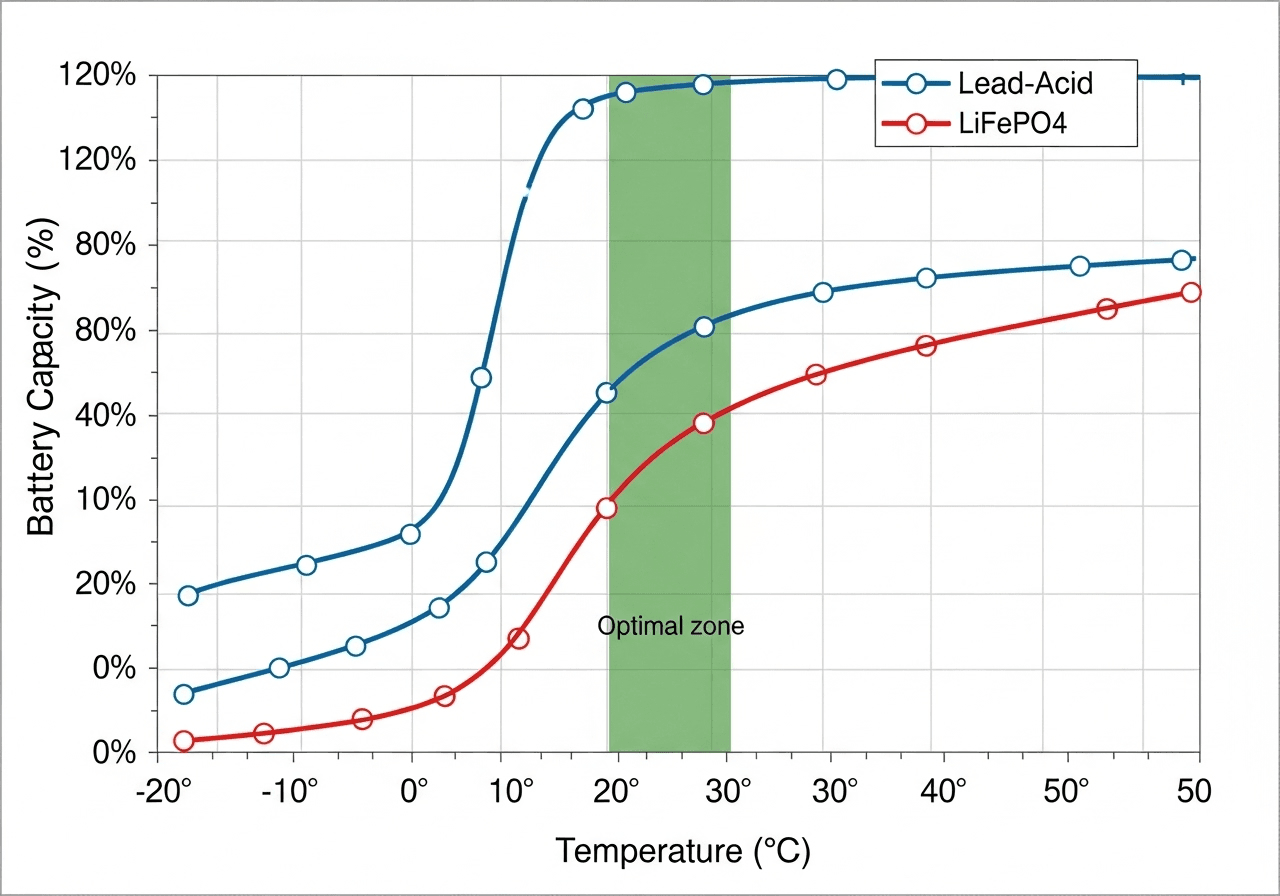

Battery performance changes with temperature:

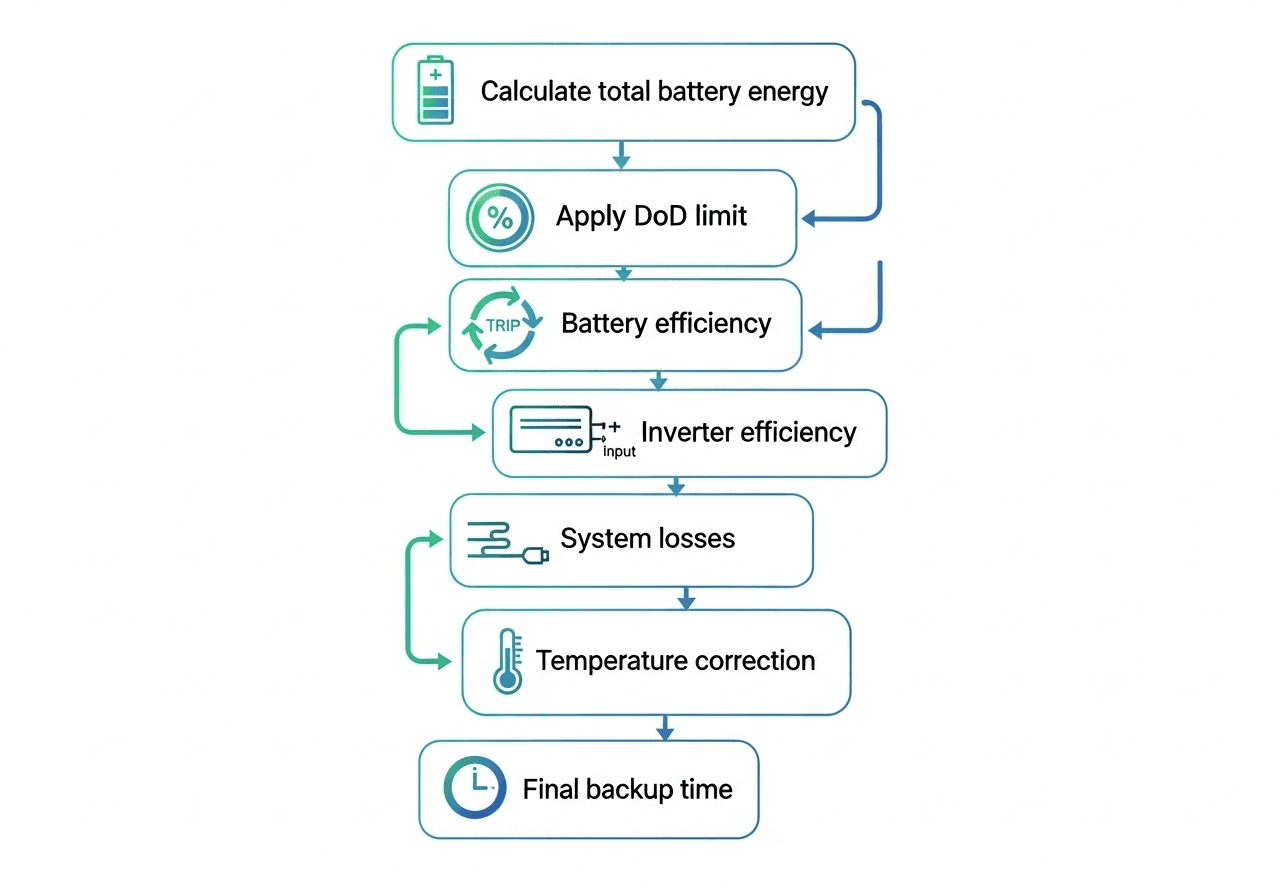

Here's how professional calculators determine your backup time:

Step 1: Calculate Total Battery Bank Energy

Step 2: Determine Usable Energy

Step 3: Apply Battery Efficiency

Step 4: Apply Inverter Efficiency

Step 5: Apply System Losses

Step 6: Apply Temperature Correction

Step 7: Calculate Backup Time

Example Calculation:

Configuration:

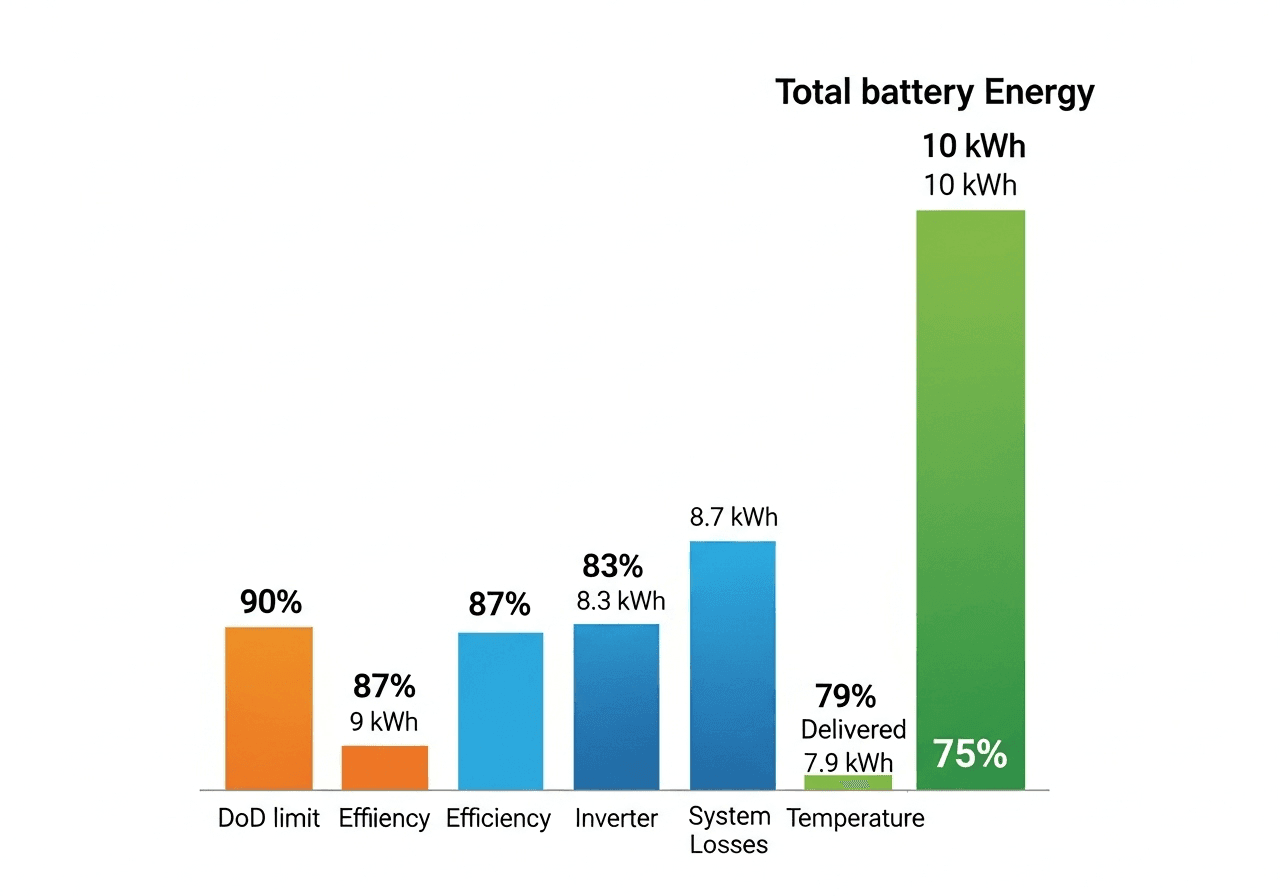

Calculation:

Different battery chemistries have distinct characteristics affecting backup duration and cost:

Real-world backup times always fall short of theoretical calculations. Here's why:

| Loss Factor | Typical Range | Impact on Backup Time | Optimization Strategy |

|---|---|---|---|

| Depth of Discharge Limit | 50-95% | 10-50% reduction | Choose lithium chemistry for higher DoD |

| Battery Round-Trip | 85-98% | 2-15% reduction | Select high-quality battery type |

| Inverter Efficiency | 85-98% | 2-15% reduction | Choose premium inverter, right-size capacity |

| Cable & Connections | 3-10% | 3-10% reduction | Minimize cable length, use proper gauge |

| Temperature Effects | 85-105% | 0-15% variation | Climate |

| Temperature Effects | 85-105% | 0-15% variation | Climate-controlled battery location |

| Peukert Effect | 5-20% | 5-20% reduction | Use lithium batteries, lower discharge rates |

| Battery Aging | 2-5% per year | Cumulative loss | Regular maintenance, proper charging |

Batteries deliver less capacity at higher discharge rates. A battery rated 100Ah at the 20-hour rate (5A discharge) might only deliver 85Ah when discharged at 10A (10-hour rate). Lithium batteries suffer less from this effect than lead-acid.

As batteries discharge, voltage drops. Your inverter maintains output voltage by drawing more current, accelerating discharge. The effect compounds toward the end of the discharge cycle.

Batteries lose 2-5% capacity annually. A three-year-old battery delivers significantly less runtime than when new. Lead-acid degrades faster than lithium.

Every 10°C temperature drop roughly halves chemical reaction rates, reducing capacity. A battery rated at 25°C delivers only 70-80% capacity at 0°C.

Inverters consume 1-3% of battery capacity even with no load connected. Battery management systems, monitoring equipment, and standby circuits drain power continuously.

Motors, compressors, and power supplies draw 2-7× their running current at startup. These surge demands briefly overload the system, triggering voltage drops and increased losses.

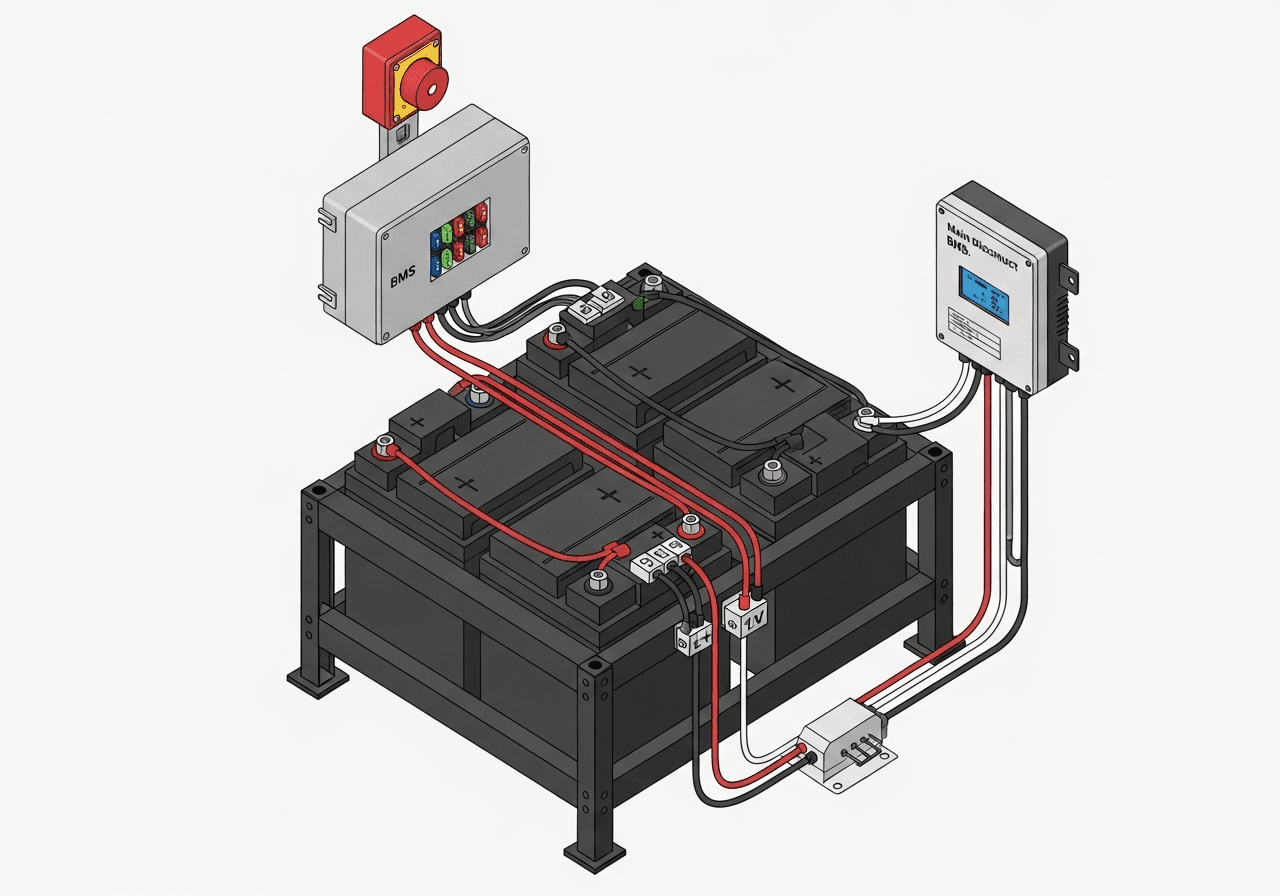

Battery configuration dramatically impacts system performance and backup duration:

Professional Recommendation: For systems with 4+ batteries, series-parallel configuration typically provides the best balance of efficiency, cost, and reliability. Target 24V or 48V system voltage for optimal inverter efficiency.

| Configuration | Voltage Effect | Capacity Effect | Advantages | Disadvantages |

|---|---|---|---|---|

| Series | Multiplies | Unchanged | Lower current, smaller cables, reduced losses | One weak battery limits all |

| Parallel | Unchanged | Multiplies | Increased redundancy, easy replacement | High current needs heavy cables |

| Series-Parallel | Increases | Increases | Balanced performance, optimal efficiency | Complex wiring, requires matching |

Want to squeeze every minute from your battery backup? Apply these professional strategies:

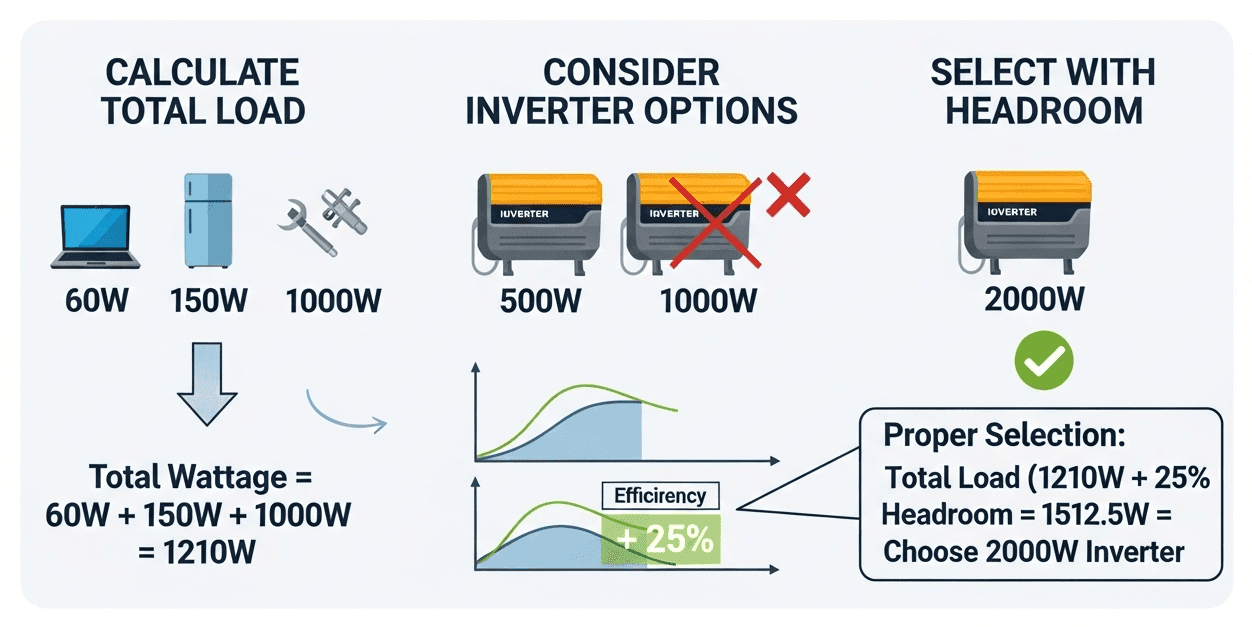

Oversized inverters waste energy through idle consumption. Select an inverter rated 20-25% above your peak load. A 500W load performs best with a 600-750W inverter.

Use the shortest practical cable runs with oversized conductors. For 12V systems, voltage drop should not exceed 3%. Consider 24V or 48V configurations for long cable runs.

Connect critical loads separately from non-essential equipment. During outages, shed non-critical loads to extend backup time for essential equipment.

Install batteries in temperature-controlled spaces (15-25°C). Every 10°C above 25°C cuts battery life in half while reducing capacity.

Clean terminals quarterly, check connections for corrosion, verify electrolyte levels (flooded batteries), and perform equalization charges as recommended.

Use quality multi-stage chargers with temperature compensation. Improper charging destroys batteries faster than deep discharges.

Stagger startup times for motors and compressors to reduce peak surge demands. Use soft-start devices where practical.

Avoid these errors that lead to disappointing backup performance:

Mistake 1: Ignoring DoD Limitations Using 100% of battery capacity destroys lead-acid batteries within months. Always respect manufacturer DoD recommendations.

Mistake 2: Forgetting Inverter Efficiency That "pure sine wave" label doesn't guarantee high efficiency. Cheap inverters waste 20-30% of battery energy as heat.

Mistake 3: Underestimating Real-World Loads Power factor, startup surges, and phantom loads increase actual consumption 15-30% beyond nameplate ratings.

Mistake 4: Mixing Battery Types or Ages Never mix different chemistries, capacities, or ages in the same bank. The weakest battery limits entire system performance.

Mistake 5: Neglecting Temperature Compensation Batteries in hot attics or cold garages perform dramatically worse than specifications suggest.

Mistake 6: Using Incorrect C-Rating Battery capacity ratings vary by discharge rate. Verify whether specifications use C20, C10, or C5 rating.

Modern battery backup calculators offer sophisticated features for accurate planning:

Input individual appliances with runtime hours to calculate realistic daily energy consumption. The calculator automatically handles:

Smart calculators automatically suggest optimal series-parallel arrangements based on:

Calculate total cost of ownership including:

Save multiple configurations to compare backup times, costs, and performance side-by-side.

Real-time visual feedback shows:

Let's examine typical applications with accurate backup calculations:

Configuration:

Calculation:

Configuration:

Calculation:

Configuration:

Calculation:

Choose appropriate battery capacity based on intended use:

| Application | Recommended Capacity | Typical Configuration | Expected Runtime |

|---|---|---|---|

| Computer UPS | 50-100Ah @ 12V | 1 × AGM | 15-30 minutes |

| Home Office | 200-400Ah @ 24V | 2-4 × LiFePO4 | 4-8 hours |

| Essential Loads | 400-800Ah @ 24V | 4-8 × AGM | 8-16 hours |

| Whole Home | 800-1600Ah @ 48V | 8-16 × LiFePO4 | 12-24 hours |

| Off-Grid Living | 1600Ah+ @ 48V | 16+ × Lead Acid/LiFePO4 | 24-48 hours |

The professional battery backup calculator includes these adjustable parameters:

The calculator provides instant visual feedback with:

Calculating battery backup duration accurately requires understanding the complex interaction between battery capacity, system voltage, load requirements, depth of discharge, and multiple efficiency factors. The simple "capacity divided by load" formula overestimates runtime by 30-50%.

Professional battery backup calculators account for battery chemistry efficiency, inverter losses, cable resistance, temperature effects, and configuration optimization. These factors typically reduce delivered energy to 70-85% of theoretical capacity.

The key takeaways:

Ready to calculate your battery backup needs? Use the interactive calculator above to determine exact backup duration for your specific configuration. Save multiple scenarios, compare options, and export detailed reports for your installation planning.

Below are direct links to the standards, handbooks, and technical resources you asked for. Each entry includes a short description and the primary link.