Brick and Block Masonry Calculator

Quickly estimate the number of bricks, blocks, and mortar required for your masonry projects with this easy-to-use calculator.

Brick & Block Masonry Calculator – Accurate Material Estimation for Your Construction Project

Free brick & block masonry calculator for accurate estimation of units, cement, sand & mortar. Get instant material quantity calculations for your construction project.

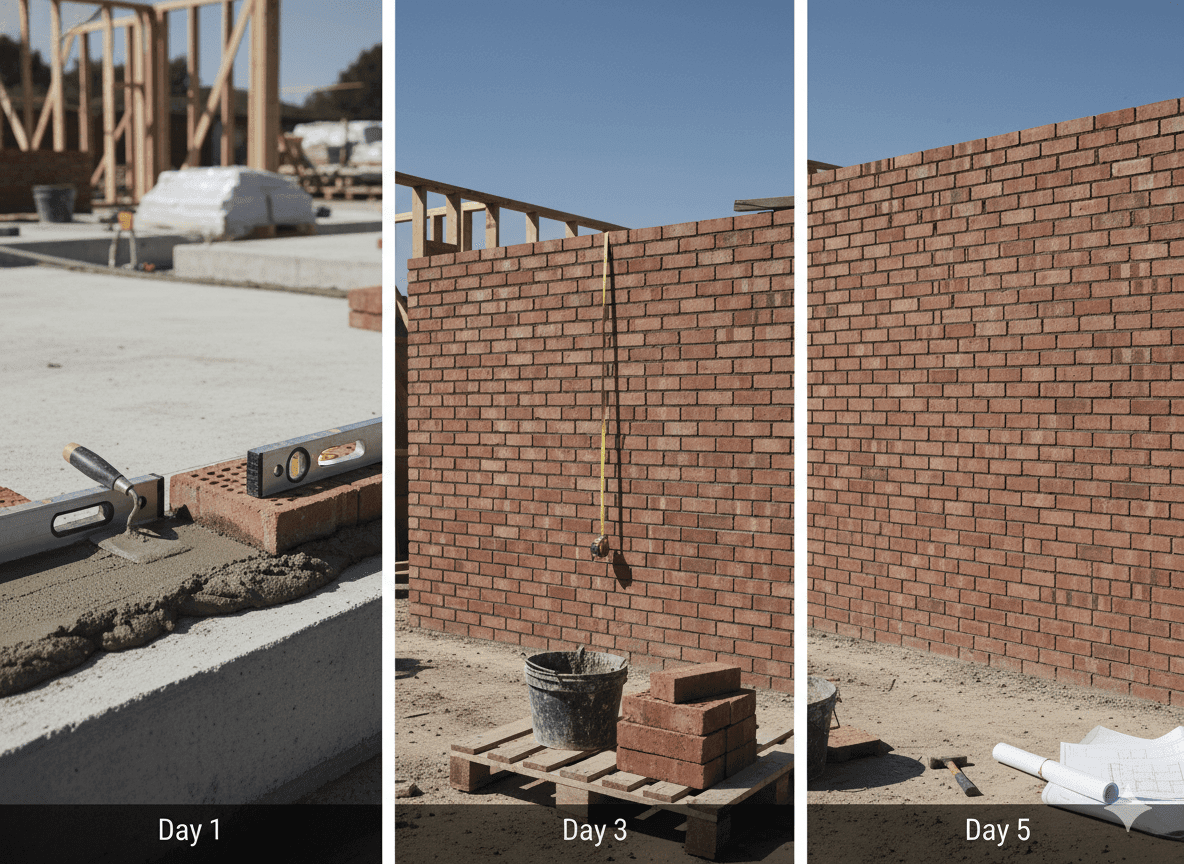

Ever stood at a construction site wondering, "Did I order enough bricks?" or "How much cement do I actually need?" You're not alone.

Here's the thing: miscalculating masonry materials costs money, time, and creates frustration. Order too little? Your project stops mid-construction. Order too much? You've wasted hundreds of dollars on materials gathering dust.

The average construction project experiences 10-15% material wastage due to poor estimation. But what if you could nail your material requirements within 2-3% accuracy before breaking ground?

That's exactly what a brick and block masonry calculator does. It takes the guesswork out of material estimation, helping you order the right quantity of bricks, blocks, cement, and sand the first time. Whether you're building a garden wall, constructing a house, or working on a commercial project, this tool becomes your best friend.

In this guide, you'll discover how masonry calculators work, the formulas behind accurate estimation, and practical tips to optimize your material ordering. Let's dive in and save you from costly material miscalculations.

What is a Brick & Block Masonry Calculator?

A brick and block masonry calculator is a digital tool that estimates the exact quantity of materials needed for wall construction. Think of it as your personal quantity surveyor that works 24/7 without charging consultation fees.

The calculator processes your wall dimensions, unit sizes, mortar joint thickness, and wastage factors to generate precise material requirements. It answers critical questions like:

- How many bricks or blocks do I need for my wall?

- What volume of mortar is required?

- How many cement bags should I purchase?

- What quantity of sand completes the mix?

Modern masonry calculators support multiple unit types including clay bricks, solid concrete blocks, hollow blocks, and AAC (Autoclaved Aerated Concrete) blocks. They also accommodate regional variations in brick sizes across South Asia, Europe, USA, and Australia.

The beauty? You get instant results without manual calculations or complex spreadsheets. Just input your measurements, and the calculator handles the math while you focus on planning your project.

Why Accurate Material Estimation Matters

Construction professionals know this truth: material estimation makes or breaks project profitability. Here's why getting it right matters tremendously.

Financial Impact

Underestimating materials by just 10% on a medium-sized residential project can add $500-$1,500 in emergency procurement costs. Rush orders often come with premium pricing, delivery surcharges, and potential project delays that multiply expenses.

Overestimation creates a different problem. Excess materials tie up working capital and create storage headaches. Those extra pallets of bricks occupying your site for months? That's money sitting idle instead of generating returns.

Project Timeline Protection

Material shortages halt construction progress. Your mason team stands idle while you scramble for supplies. A single day of construction delay can cost $200-$500 in labor costs alone, not counting the domino effect on subsequent trades.

Quality Control

Accurate estimation ensures material consistency. When you order the right quantity upfront, all units come from the same production batch. This maintains color uniformity and dimensional consistency that's impossible to achieve with multiple small orders spread across weeks.

Environmental Responsibility

The construction industry generates nearly 40% of global waste. Precise material calculation reduces unnecessary production, transportation emissions, and landfill burden. Every brick you don't waste is a small victory for sustainable construction.

Professional contractors understand that the 30 minutes spent on accurate calculation saves countless hours and dollars downstream. That's not just good math—it's good business.

Understanding Brick vs Block Masonry

Not all masonry units are created equal. Understanding the fundamental differences between bricks and blocks helps you choose the right calculator settings and interpret results accurately.

Clay Bricks – The Traditional Choice

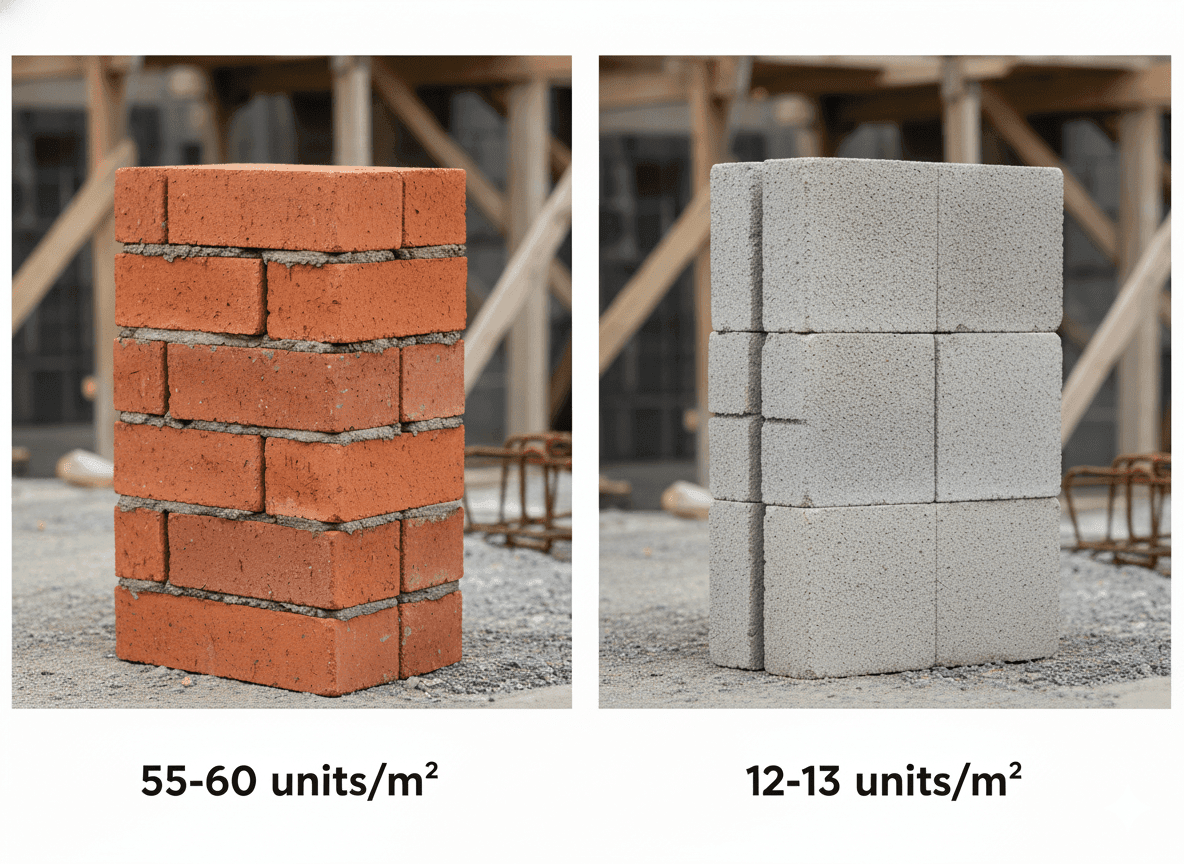

Clay bricks are the classic masonry unit, typically measuring around 190mm × 90mm × 90mm in South Asia. They're compact, solid, and require approximately 55-60 units per square meter of wall area.

Brickwork offers excellent load-bearing capacity and thermal mass. The smaller unit size provides design flexibility for curved walls and decorative patterns. However, brick construction is labor-intensive and requires skilled masons for quality workmanship.

Concrete Blocks – The Modern Alternative

Concrete blocks are larger units, commonly sized at 390mm × 190mm × 190mm for standard hollow blocks. You need only 12-13 blocks per square meter, dramatically reducing laying time and labor costs.

Blocks come in three varieties:

- Solid blocks: Dense, high-strength units for load-bearing walls

- Hollow blocks: Lightweight with internal cavities, offering thermal insulation

- AAC blocks: Ultra-lightweight autoclaved aerated concrete with superior insulation

Block construction proceeds 3-4 times faster than brickwork due to larger unit sizes. The reduced mortar joints also mean lower cement consumption and faster curing times.

Which Should You Choose?

Bricks excel in residential construction, decorative applications, and regions with strong traditional preferences. Blocks dominate commercial construction, high-rise buildings, and projects prioritizing speed and cost efficiency.

Your masonry calculator must account for these differences. Brick calculations use smaller unit dimensions and higher units-per-square-meter ratios. Block calculations accommodate larger sizes and adjust mortar volume accordingly.

Mortar Volume Requirements by Unit Type

| Unit Type | Mortar Fraction (%) | Cement Consumption | Weight Category | Best Application |

|---|---|---|---|---|

| Clay Bricks | 28% | High | Medium (18-20 kg/unit) | Residential walls, decorative |

| Solid Concrete Blocks | 18% | Medium | Heavy (25-30 kg/unit) | Load-bearing walls, commercial |

| Hollow Concrete Blocks | 12% | Low-Medium | Light (10-15 kg/unit) | Partition walls, non-structural |

| AAC/CLC Blocks | 8% | Very Low | Ultra-light (6-10 kg/unit) | Insulation, lightweight construction |

How the Brick & Block Masonry Calculator Works

Let's pull back the curtain and see the mathematics powering accurate material estimation. Understanding these formulas helps you verify results and make informed adjustments.

Step 1: Calculate Net Wall Area

The calculator starts with your gross wall area and subtracts openings (doors, windows, ventilators):

Net Area = Wall Area - Openings Area

For a 10m² wall with a 2m² door opening, your net masonry area is 8m². This is the actual surface requiring bricks or blocks.

Step 2: Determine Units Required

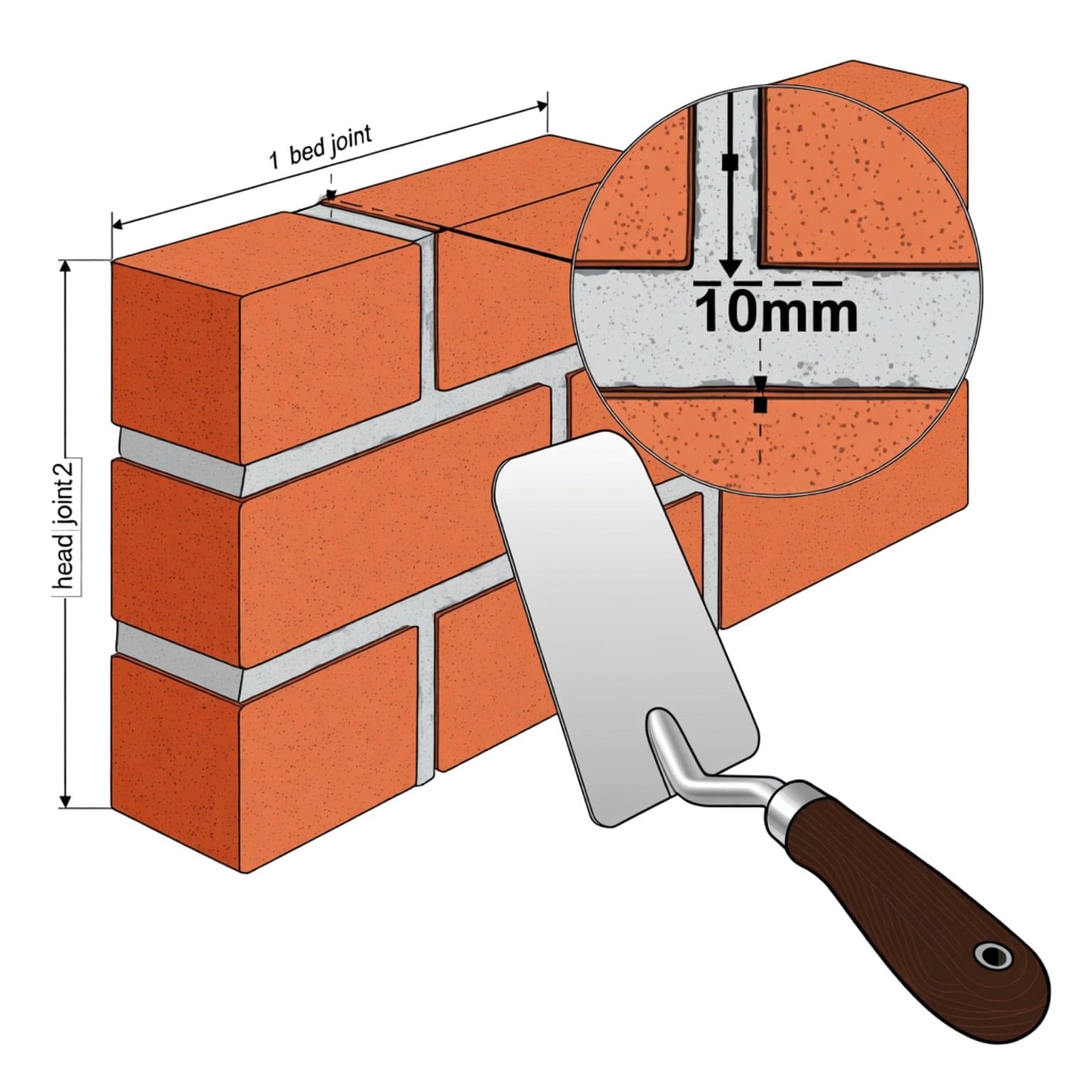

The calculator computes how many units fit per square meter based on unit dimensions and mortar joint thickness:

Units per m² = 1 / [(Length + Joint Thickness) × (Height + Joint Thickness)]

For a standard 190mm × 90mm brick with 10mm joints:

- Effective cell area = (0.19 + 0.01) × (0.09 + 0.01) = 0.02m²

- Units per m² = 1 / 0.02 = 50 units

Some calculators allow manual override if you have manufacturer specifications or local standards that differ from calculated values.

Total Units (net) = Net Area × Units per m²

Step 3: Add Wastage Factor

Real construction involves breakage, cutting, and quality rejection. The calculator applies a wastage percentage (typically 3-5%):

Final Units = Net Units × (1 + Wastage%/100)

This ensures you have adequate materials to complete the wall without mid-project shortages.

Step 4: Calculate Mortar Volume

Mortar volume depends on wall thickness, joint thickness, and unit type. The calculator uses empirical mortar fractions:

- Clay bricks: ~28% of wall volume

- Solid blocks: ~18% of wall volume

- Hollow blocks: ~12% of wall volume

- AAC blocks: ~8% of wall volume

Wall Volume = Net Area × Wall Thickness

Mortar Volume = Wall Volume × Mortar Fraction

Step 5: Determine Cement and Sand Quantities

Mortar consists of cement and sand in specific ratios (1:4, 1:5, or 1:6). The calculator converts mortar volume to cement bags and sand volume:

Cement Volume = (Mortar Volume / (1 + Sand Ratio)) × 1.33

The 1.33 factor accounts for bulking during mixing and compaction losses.

For a 1:6 mix with 0.5m³ mortar:

- Cement volume = (0.5 / 7) × 1.33 = 0.095m³

- Cement bags = (0.095 × 1440 kg/m³) / 50 kg/bag ≈ 3 bags

Sand Volume = Mortar Volume - Cement Volume

Step 6: Generate Results

The calculator presents comprehensive material requirements: total units, cement bags, sand volume, and mortar quantity. Advanced calculators also provide 2D wall previews showing approximate unit layout.

Key Features of an Advanced Masonry Calculator

Modern masonry calculators pack powerful features that transform material estimation from tedious to effortless. Here's what separates excellent calculators from basic ones.

Multi-Unit Support

Top calculators handle diverse unit types with preset dimensions for clay bricks, solid blocks, hollow blocks, and AAC blocks. Regional presets automatically adjust for South Asian, European, American, and Australian standard sizes.

Unit Conversion Flexibility

Work in your preferred measurement system. Quality calculators offer seamless conversion between:

- Metric (mm, meters, m²) and Imperial (inches, feet, ft²)

- Different area units without manual recalculation

Real-Time Calculation

Forget clicking "Calculate" repeatedly. Advanced tools recalculate instantly as you adjust inputs. Change wall height by 1 meter? Results update immediately.

Customizable Mix Ratios

Different applications require different mortar strengths. Professional calculators support common mix ratios (1:4, 1:5, 1:6) with automatic cement and sand adjustments.

Wastage Optimization

Intelligent wastage calculation based on:

- Unit type (bricks have higher breakage than blocks)

- Project complexity (curved walls need more material)

- Site conditions (remote locations benefit from higher buffers)

Visual Preview

2D wall rendering shows approximate unit layout, helping visualize the finished structure and verify unit count makes sense for your wall dimensions.

Offline Functionality

The best calculators work without internet connectivity. Once loaded, they operate entirely in your browser—perfect for construction sites with limited connectivity.

Export and Sharing

Generate material lists you can share with suppliers, contractors, and project managers. Some calculators create PDF reports or printable summaries.

Step-by-Step Guide: Using the Masonry Calculator

Let's walk through a practical example to demonstrate how simple and powerful these calculators are.

Scenario: Building a garden wall, 15 feet long and 6 feet high, with a 3×6 feet gate opening, using standard clay bricks.

Step 1: Select Unit Type

Choose "Brick" mode and select your region (or keep "Custom" for manual control). For this example, we'll use South Asian standard bricks.

Step 2: Input Wall Dimensions

- Wall area: 15 ft × 6 ft = 90 ft²

- Switch to ft² units using the area toggle

- Opening area: 3 ft × 6 ft = 18 ft²

- Net area: 72 ft²

Step 3: Verify Unit Dimensions

Default South Asian brick: 190mm × 90mm × 90mm (roughly 7.5″ × 3.5″ × 3.5″). These dimensions appear automatically with the regional preset.

Step 4: Set Construction Parameters

- Mortar joint thickness: 10mm (standard)

- Wall thickness: 110mm (single brick width)

- Mix ratio: 1:6 (common for non-load-bearing walls)

- Wastage: 5% (accounting for breakage and cuts)

Step 5: Review Results

The calculator instantly displays:

- Units required: 396 bricks (net) + 5% = 416 bricks (final)

- Cement: 2 bags (50kg each)

- Sand: 0.18m³ (approximately 6.4 ft³)

- Mortar volume: 0.22m³

Step 6: Adjust if Needed

Notice you're using hollow blocks instead? Switch unit type, and watch all calculations update automatically for the different mortar requirements and unit coverage.

Step 7: Order Materials

Armed with precise quantities, contact suppliers confidently. Add a small buffer (2-3%) for site-specific conditions, but avoid the traditional 15-20% overestimation that wastes money.

The entire process takes 2-3 minutes compared to 20-30 minutes of manual calculation prone to arithmetic errors.

Regional Variations in Brick and Block Sizes

Construction isn't one-size-fits-all. Material dimensions vary significantly across regions, affecting your calculations dramatically.

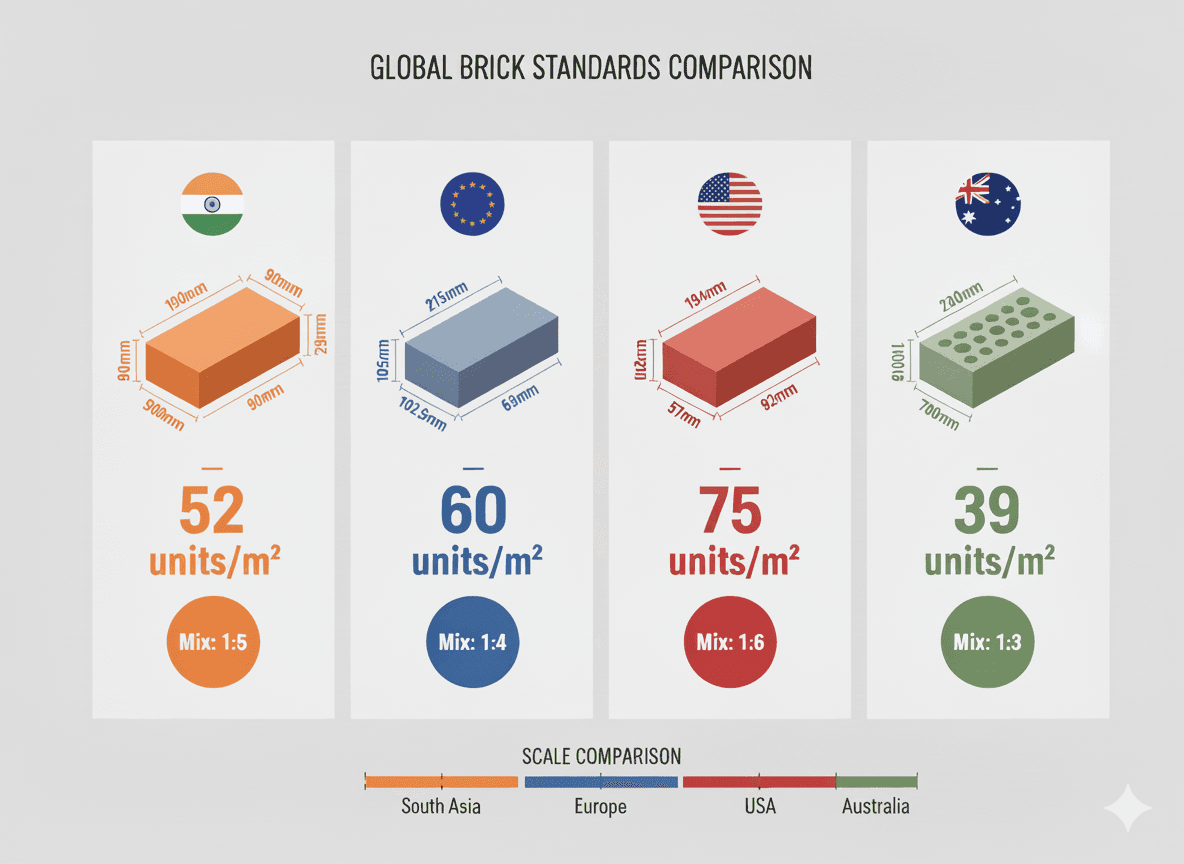

South Asia (India, Pakistan, Bangladesh)

Standard clay brick: 190mm × 90mm × 90mm

- Approximately 55-60 bricks per m²

- Common mix ratio: 1:6 for general construction

- Wall thickness: 110mm (single), 230mm (double)

Europe (UK, Germany, Netherlands)

Standard brick: 215mm × 65mm × 102.5mm

- Approximately 50-52 bricks per m²

- Common mix ratio: 1:5 for better strength

- Metric system dominance

United States

Modular brick: 194mm × 57mm × 92mm (7.625″ × 2.25″ × 3.625″)

- Approximately 60-65 bricks per m²

- Common mix ratio: 1:4 for structural applications

- Imperial measurements still prevalent

Australia

Standard brick: 230mm × 76mm × 110mm

- Approximately 48-50 bricks per m²

- Common mix ratio: 1:6 for residential work

- Metric system standard

Regional Brick & Block Size Standards

| Region | Standard Size (L×H×W) | Units per m² | Common Mix Ratio | Measurement System |

|---|---|---|---|---|

| South Asia | 190mm × 90mm × 90mm | 55-60 | 1:6 | Metric |

| Europe | 215mm × 65mm × 102.5mm | 50-52 | 1:5 | Metric |

| United States | 194mm × 57mm × 92mm (7.625″ × 2.25″ × 3.625″) | 60-65 | 1:4 | Imperial/Metric |

| Australia | 230mm × 76mm × 110mm | 48-50 | 1:6 | Metric |

| Concrete Blocks | 390mm × 190mm × 190mm | 12-13 | 1:5 | Universal |

Why This Matters

Using incorrect regional dimensions creates 10-15% estimation errors. A calculator using American brick dimensions for a European project underestimates material by approximately 8-10 bricks per square meter.

Always verify your calculator's regional settings match your actual material specifications. When in doubt, measure a sample unit from your supplier and input custom dimensions.

Common Mistakes to Avoid When Estimating Materials

Even with calculators, certain errors creep into material estimation. Avoid these common pitfalls for accurate results.

Mistake 1: Ignoring Mortar Joint Thickness

Many assume joint thickness is negligible. Wrong. A 10mm joint reduces usable brick area by 5-7%, significantly affecting unit count. Always input accurate joint specifications.

Mistake 2: Forgetting Wall Thickness

Single-width walls (110mm) use far less mortar than double-width walls (230mm). Ensure your calculator accounts for actual wall thickness, not just surface area.

Mistake 3: Insufficient Wastage Allowance

The 3% default wastage works for straightforward walls. Increase to 5-8% for:

- Curved or angled walls requiring extensive cutting

- Inexperienced labor teams

- Poor-quality materials with higher breakage rates

Mistake 4: Mixing Unit Systems

Entering length in inches but area in square meters creates catastrophic calculation errors. Stick to one unit system throughout or use calculators with automatic conversion.

Mistake 5: Overlooking Half-Brick Adjustments

Wall corners, returns, and headers require cut bricks or special units. Add 2-3% extra for complex layouts with multiple corners and junctions.

Mistake 6: Not Verifying Supplier Dimensions

Manufacturer specifications sometimes differ from standard dimensions. Measure actual units before finalizing orders, especially with imported materials.

Mistake 7: Calculating Gross Area Only

Failing to subtract openings (doors, windows, vents) inflates material requirements by 15-25% for typical residential walls. Always input net masonry area.

Double-check your inputs before ordering. The calculator's accuracy depends entirely on input accuracy.

Recommended Wastage Allowances

| Project Type | Wastage % | Factors Considered | Risk Level |

|---|---|---|---|

| Straightforward Walls | 3-5% | Minimal cutting, experienced labor | Low |

| Complex Layouts | 5-8% | Multiple corners, curved sections | Medium |

| Decorative/Intricate Work | 8-12% | Custom patterns, extensive cutting | High |

| Remote/Difficult Sites | 8-10% | Limited access, material handling issues | High |

| Low-Quality Materials | 10-15% | High breakage rate, dimensional variation | Very High |

Optimizing Mortar Mix Ratios for Different Applications

Not all mortar mixes are created equal. Choosing the right cement-to-sand ratio impacts strength, cost, and workability.

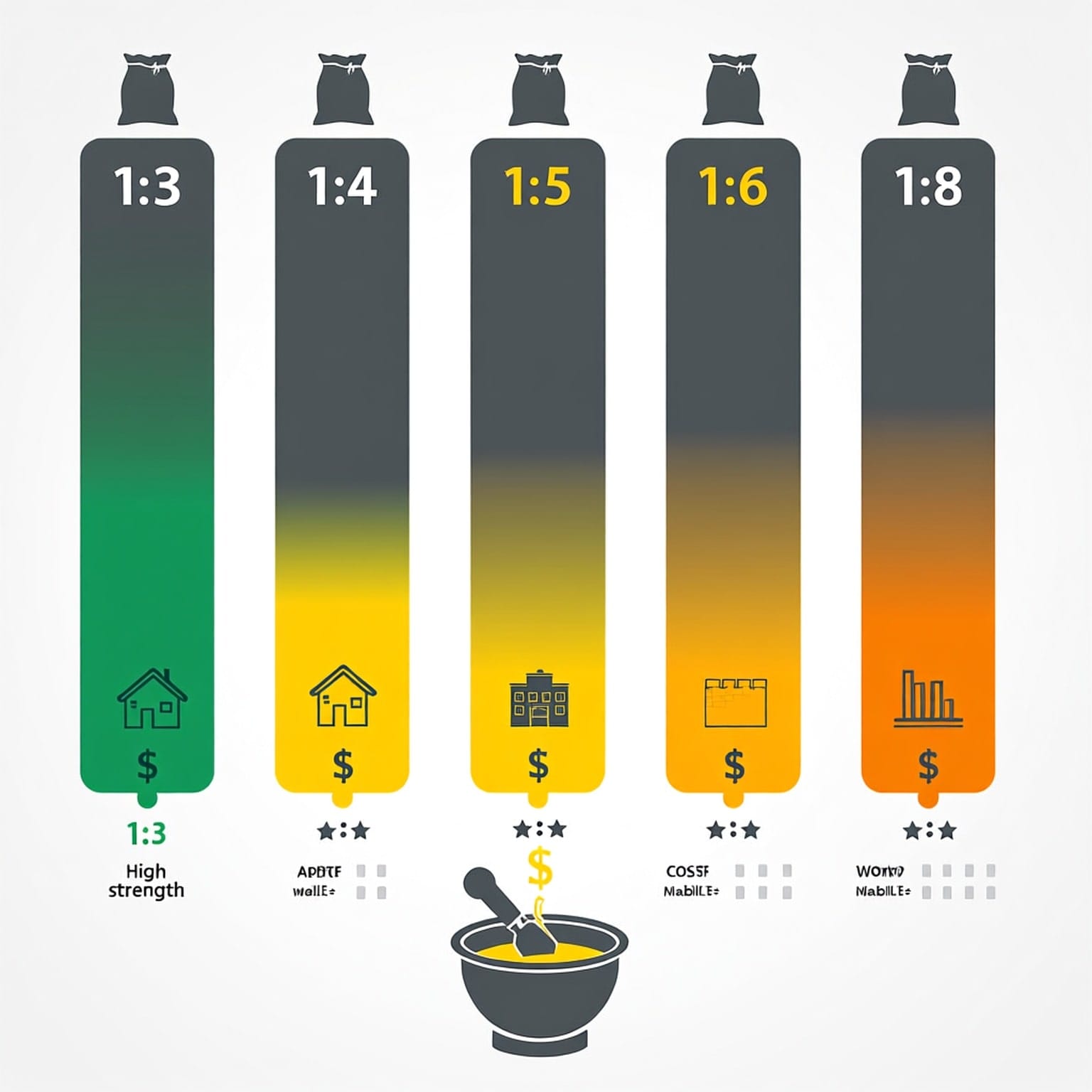

1:3 Mix – Maximum Strength

- Applications: Load-bearing walls, structural elements, high-stress areas

- Strength: 7-10 MPa compressive strength

- Cost: Highest due to cement content

- Workability: Stiff, requires skilled application

1:4 Mix – High Strength

- Applications: Exterior walls, foundations, retaining walls

- Strength: 5-7 MPa compressive strength

- Cost: Moderate-high

- Workability: Good balance of strength and handleability

1:5 Mix – General Purpose

- Applications: Internal walls, general construction, residential projects

- Strength: 3-5 MPa compressive strength

- Cost: Moderate

- Workability: Excellent for most applications

1:6 Mix – Economical

- Applications: Non-load-bearing walls, partitions, garden walls

- Strength: 2-3 MPa compressive strength

- Cost: Lowest due to reduced cement content

- Workability: Very workable, ideal for large areas

1:8 Mix – Minimal Strength

- Applications: Temporary structures, plastering base

- Strength: <2 MPa compressive strength

- Cost: Minimal cement usage

- Workability: Excellent but weak bonding

Choose based on structural requirements, not just cost. Using 1:6 mix where 1:4 is needed saves $50 on cement but risks structural failure costing thousands in repairs.

Your masonry calculator adjusts cement and sand quantities automatically when you change mix ratios, ensuring material proportions stay accurate.

Mortar Mix Ratios Comparison

| Mix Ratio (C:S) | Strength (MPa) | Applications | Cost Level | Workability |

|---|---|---|---|---|

| 1:3 | 7-10 MPa | Load-bearing walls, structural elements | High | Stiff |

| 1:4 | 5-7 MPa | Exterior walls, foundations, retaining walls | Moderate-High | Good |

| 1:5 | 3-5 MPa | Internal walls, residential projects | Moderate | Excellent |

| 1:6 | 2-3 MPa | Non-load-bearing walls, partitions | Low | Very Good |

| 1:8 | <2 MPa | Temporary structures, plastering base | Very Low | Excellent |

Frequently Asked Questions (FAQ)

Conclusion

Accurate material estimation isn't just about avoiding waste—it's about professional construction management that saves time, money, and frustration. The brick and block masonry calculator transforms complex mathematical formulas into instant, reliable material quantities you can trust.

Whether you're a homeowner planning a DIY project or a contractor managing multiple sites, mastering this tool gives you confidence in every material order. No more guesswork, no more expensive rush orders, no more pallets of unused bricks collecting dust.

Remember the key principles: input accurate dimensions, account for regional variations, choose appropriate mix ratios, and include realistic wastage factors. These simple steps ensure your calculations align with real-world construction conditions.

The calculator handles the complex mathematics—unit coverage, mortar fractions, cement conversions—while you focus on bringing your construction vision to life. That's smart project management.

Ready to start your next masonry project with confidence? Use a brick and block masonry calculator today and experience the difference accurate estimation makes. Your budget, timeline, and sanity will thank you.

Call to Action: Bookmark this guide, share it with fellow builders, and make material estimation the easiest part of your next construction project. Have questions about specific applications? Drop a comment below and let's build better together.

References

- British Standards Institution (BSI) – BS EN 771-1:2011+A1:2015 — Specification for masonry units.

- American Concrete Institute (ACI) – ACI 530-13 — Building Code Requirements for Masonry Structures.

- Bureau of Indian Standards (BIS) – IS 1077:1992 — Common Burnt Clay Building Bricks Specification.

- ASTM International – ASTM C90 — Standard Specification for Loadbearing Concrete Masonry Units.

- Concrete Masonry Association of Australia (CMAA) – Technical Guidelines — Masonry design and performance standards.

- National Concrete Masonry Association (NCMA) – TEK Manual — Concrete masonry design and construction reference.

- Construction Industry Research and Information Association (CIRIA) – Masonry Design Guide — Practical design and construction guidelines.