Regional Sizing Considerations: USA, Canada, Europe, Australia, Asia

United States (NEC Compliance)

Code requirements:

- NEC Article 706: Energy Storage Systems

- Minimum wire sizing per ampacity tables

- Disconnect switches required

- GFCI protection for residential

- Fire safety (NFPA 855 for >600V or >50 kWh)

Regional climate adjustments:

Hot climates (Arizona, Texas, Florida):

- Add 10-15% capacity for temperature derating

- Battery cooling/ventilation critical

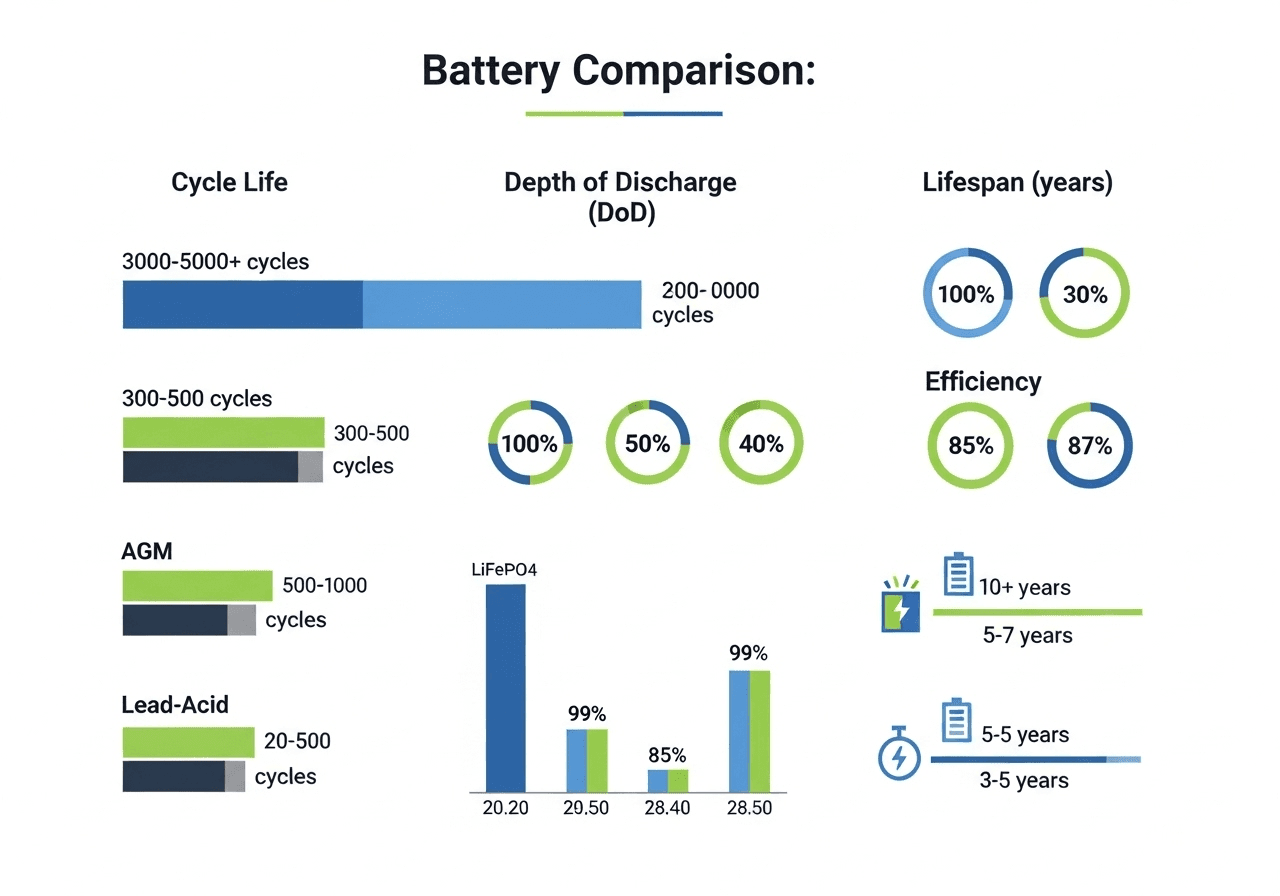

- Prefer LFP (better heat tolerance)

Cold climates (Alaska, Minnesota, Montana):

- Add 25-30% capacity for -20°C operation

- Battery heating required

- AGM or LFP with cold-weather BMS

Typical residential system (California):

- 48V, 13.5 kWh (Tesla Powerwall equivalent)

- LFP, 85% DOD, 92% efficiency

- Covers 4-6 hours evening TOU avoidance

Canada (CSA Standards)

Key differences from USA:

- Higher safety margins (15-20%) due to cold

- Battery heating systems mandatory in most regions

- Voltage drop calculations critical (cold increases resistance)

Saskatchewan example:

- Winter: -30°C common → 40% capacity loss for lead-acid

- Recommendation: LFP with integrated heaters + 30% oversizing

- Insulated battery enclosures standard

Ontario residential typical:

- 48V, 15-20 kWh systems

- Grid-tie with backup (frequent ice storms)

- Net metering optimization

Europe (IEC Standards)

Code framework:

- IEC 60364-7-712: PV system installations

- CE marking mandatory

- Higher efficiency requirements (prefer >92%)

Country-specific notes:

Germany:

- KfW incentives for solar + storage

- Focus on self-consumption optimization

- Common: 5-10 kWh systems for 4 kW solar

UK:

- G99 grid connection requirements

- VAT zero-rated for solar + storage (as of 2024)

- Typical: 48V, 9.5 kWh (Powerwall size)

Spain:

- High solar irradiance → smaller batteries often sufficient

- Focus on evening peak shaving

- Common: 5-7 kWh for 3-5 kW solar

Nordics (Sweden, Norway, Finland):

- Extreme cold → battery heating mandatory

- Off-grid cabins common → 24-48h autonomy

- Prefer LFP with -20°C rating

Australia (AS/NZS Standards)

Code requirements:

- AS/NZS 5139:2019: Electrical installations—Safety of battery systems

- Strict fire safety (bushfire zones)

- Hot climate derating mandatory

Climate challenges:

- Queensland summer: 35-45°C ambient → 15-20% capacity derating

- Northern Territory: Extreme heat + humidity

- Southern states: Moderate (similar to California)

- Typical residential (Sydney):

- 48V, 10-13 kWh systems

- LFP dominant (95%+ of new installs)

- Solar FiT optimization (feed-in tariff)

- Battery enclosures: shaded, ventilated

- Regional variations:

- Queensland:

- Highest derating requirements (20%)

- Battery cooling often needed

- Focus on afternoon solar storage

- Victoria:

- Solar Victoria rebates (up to $3,850)

- Time-of-use optimization critical

- 6-10 kWh average system size

- Western Australia:

- High electricity costs → larger systems (12-15 kWh)

- Off-grid common in rural areas

- 24-48h autonomy for remote properties

Asia: Emerging Markets & Unique Challenges

South Asia (Pakistan, India, Bangladesh)

- Grid challenges:

- Load shedding: 4-12 hours daily in many areas

- Voltage instability (160-260V swings)

- Frequent brownouts

- Typical system design:

- System voltage: 24V (affordability) or 48V (efficiency)

- Autonomy: 8-16 hours (full overnight + daytime backup)

- Battery preference: Shifting from lead-acid to LFP (cost declining)

- Safety margin: 20% (high temperatures, aging grid)

- Pakistan example (Karachi residential):

- Load: 2,000W (fans, lights, TV, fridge)

- Duration: 12 hours

- Temperature: 40°C in summer

- Calculation:

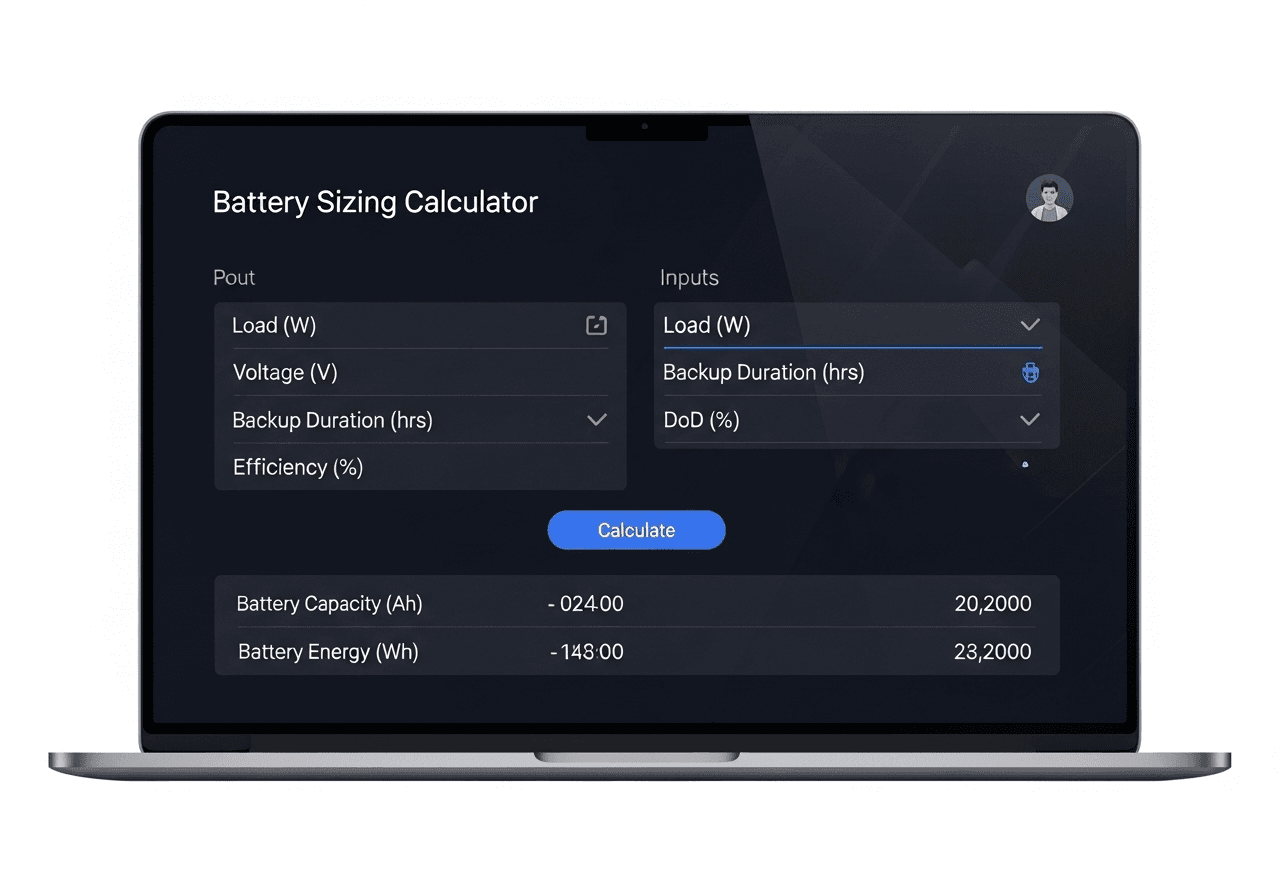

-

Required Ah = (2,000W × 12h) ÷ (24V × 0.88 × 0.75)

Required Ah = 24,000 ÷ 15.84 = 1,515 Ah

With 20% safety + 15% temp derating:

Adjusted = 1,515 × 1.20 × 1.15 = 2,091 Ah

Using 200 Ah, 12V batteries:

Series: 24V ÷ 12V = 2S

Parallel: 2,091 ÷ 200 = 10.5 → 11P

Configuration: 2S × 11P = 22 batteries

- Cost consideration: Lead-acid still dominant ($150-200 per battery) vs. LFP ($400-500)

East Asia (China, Japan, South Korea)

- Characteristics:

- Advanced battery manufacturing (CATL, BYD, LG, Samsung)

- High-efficiency requirements (>92% standard)

- Smart grid integration

- EV-to-home (V2H) emerging

- Japan specifics:

- Earthquake resilience critical

- Backup systems mandatory in many areas

- 48V, 7-10 kWh typical residential

- Government subsidies available

- China developments:

- Sodium-ion batteries emerging (2025+)

- Large-scale home storage adoption

- Integration with EV charging

- 48-51.2V systems standard

Middle East (UAE, Saudi Arabia, GCC)

- Extreme climate challenges:

- Summer temperatures: 45-50°C ambient

- Battery derating: 20-25% required

- Dust accumulation affects solar (cleaning needed)

- High AC loads (cooling dominates)

- Typical commercial system (Dubai office):

- Load: 15 kW (heavy AC, IT equipment)

- Duration: 4 hours (peak demand reduction)

- System: 110V or 230V DC (industrial scale)

Calculation:

Required Ah = (15,000W × 4h) ÷ (110V × 0.92 × 0.80)

Required Ah = 60,000 ÷ 80.96 = 741 Ah

With 15% safety + 20% heat derating:

Adjusted = 741 × 1.15 × 1.20 = 1,023 Ah

Using 100 Ah, 51.2V LFP modules:

Series: 110V ÷ 51.2V = 2.15 → 2S (with voltage buffer)

Parallel: 1,023 ÷ 100 = 10.2 → 11P

Configuration: 2S × 11P = 22 modules

Total: ~112V, 1,100 Ah = 123 kWh system

Cooling requirements: Active cooling often needed, adds 5-8% to power budget