Inputs

Runtime Summary

Load vs Runtime (Preview)

Fuel Depletion Timeline

Scenario & Tools

Quick presets to validate the model. Also adjust view and export results.

Accurate runtime prediction with environmental compensation, multi-unit support, alerts and interactive charts.

Quick presets to validate the model. Also adjust view and export results.

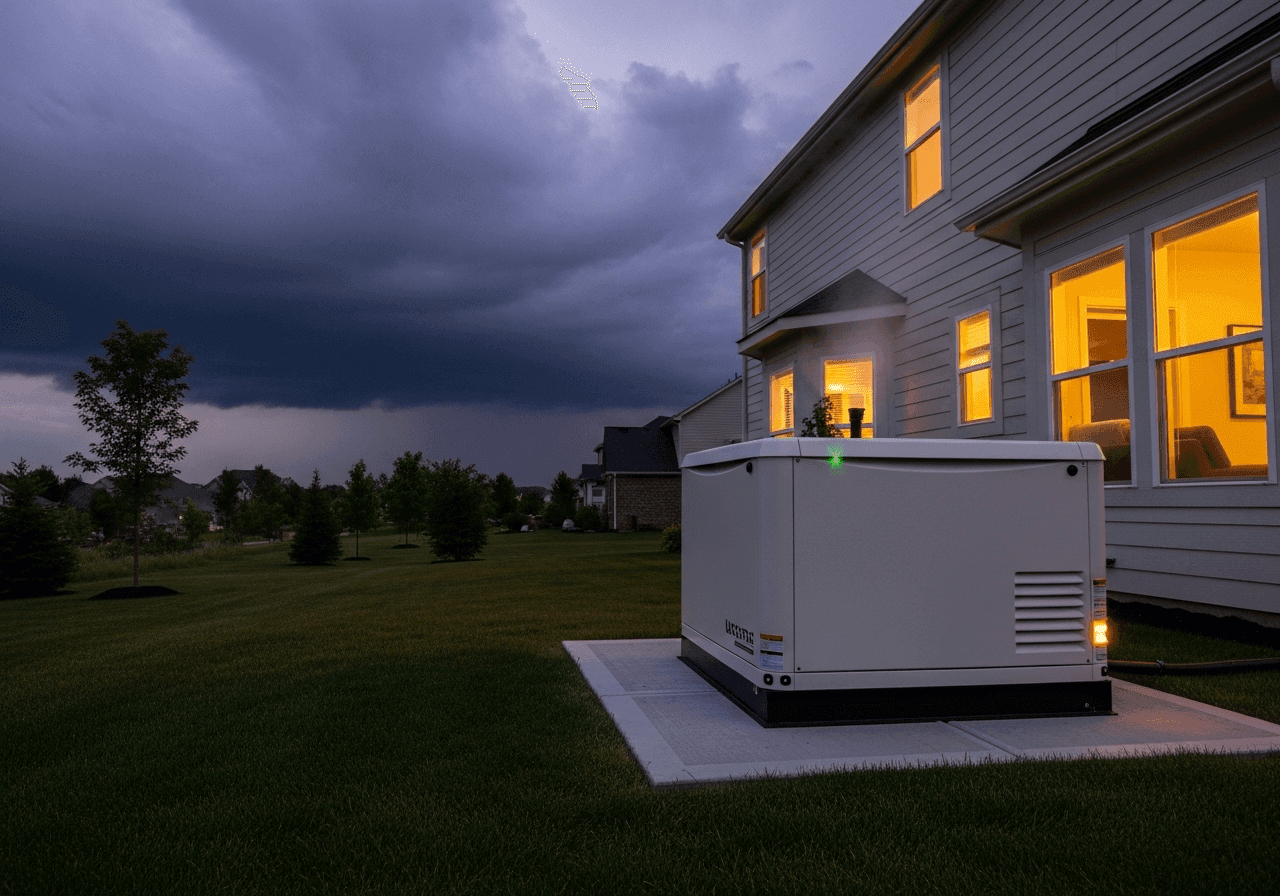

Ever been caught in a storm wondering, "How long will my generator actually last?" You're not alone. Here's the thing – most people just guess their generator runtime, and that's a recipe for disaster. Picture this: It's 2 AM, the power's been out for hours, your family's asleep, and suddenly everything goes dark again because you ran out of fuel.

What if you could know exactly how long your generator will run? Not just a rough estimate, but precise calculations that factor in your actual load, fuel type, temperature, and even altitude? That's exactly what a professional smart generator runtime calculator does.

Whether you're a homeowner preparing for the next blackout, a construction manager coordinating site power, or an industrial operator managing critical systems, understanding your generator's runtime isn't just convenient – it's essential. In this comprehensive guide, we'll dive deep into how these calculators work, the science behind the numbers, and how you can use them to never be caught off guard again.

Let's unlock the power of predictive generator management together.

A smart generator runtime calculator is your digital crystal ball for backup power. Think of it as a GPS for your fuel tank – instead of telling you how to get somewhere, it tells you how long you can stay running.

Unlike basic calculators that just divide tank size by consumption rate, professional smart calculators account for real-world variables that dramatically affect runtime. These intelligent tools consider load fluctuations, ambient temperature, altitude effects, and even fuel quality to give you accurate predictions.

The calculator doesn't just crunch numbers – it adapts. Running your generator at 40% load uses far less fuel per hour than at 90% load, but not in a simple linear way. Smart calculators use non-linear consumption curves that mirror how generators actually behave in the field.

For residential users, this means peace of mind during power outages. For industrial operations, it translates to millions saved in downtime prevention. A construction company in Ontario recently avoided a $50,000 project delay simply by using accurate runtime predictions to schedule refueling before their generator ran dry during a critical concrete pour.

The difference between guessing and knowing can literally be the difference between keeping your freezer running or losing $500 worth of food, between maintaining hospital operations or risking patient safety, between meeting your deadline or facing contract penalties.

Guessing your generator runtime is like driving with your eyes closed – you might get lucky, but eventually, something bad happens. Let me show you why precision matters.

When Hurricane Fiona hit Atlantic Canada in 2022, families who miscalculated their generator runtime faced days without power. Medical devices shut down. Food spoiled. Elderly residents suffered in the cold. One miscalculation, and you're not just inconvenienced – you're in danger.

Consider a data center in Frankfurt. Their backup generators support millions in transactions every hour. Running out of fuel isn't an option – it's catastrophic. With accurate runtime calculations, they schedule refueling with surgical precision, maintaining 99.99% uptime while optimizing fuel costs.

For construction sites across Australia, inaccurate runtime estimates lead to work stoppages. A site manager in Sydney told us his team lost 8 hours of productivity when their generator died mid-pour. The concrete had to be jackhammered out and reordered. Total cost? $12,000 – all because they thought they had "enough fuel."

Here's something most people don't think about: running a generator to complete empty damages the engine. Sediment at the bottom of the tank gets sucked into the fuel system, potentially causing thousands in repair costs. Professional runtime calculators include reserve recommendations, warning you before you hit that dangerous zone.

In Europe, where carbon reporting is increasingly mandatory, knowing your exact fuel consumption helps you calculate and offset your emissions. A smart calculator shows you precisely how much CO₂ you're producing per hour, helping you make environmentally conscious decisions about load management.

Accurate runtime calculations give you control. You can plan refueling during business hours instead of emergency midnight runs. You can optimize your load to stretch fuel during extended outages. You can budget fuel costs precisely instead of over-ordering or, worse, running short.

Knowledge isn't just power here – it's literally the power staying on.

Before we dive into complex calculations, let's break down the fundamentals. Your generator doesn't burn fuel at a constant rate – it's more dynamic than that.

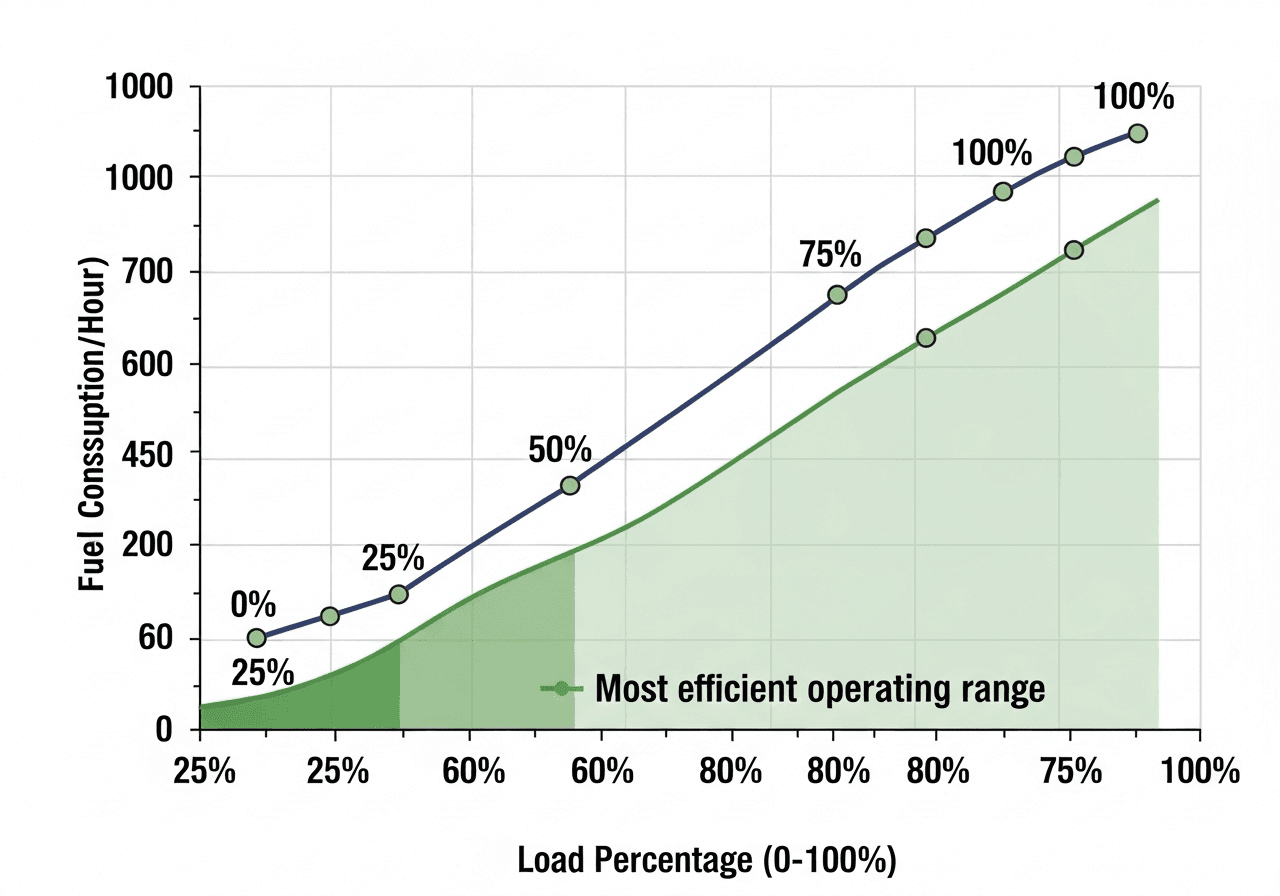

Most people think a generator at 50% load uses 50% of its maximum fuel consumption. Wrong. Generators maintain what's called "base consumption" even at idle – typically around 25% of maximum consumption. This covers the engine running, cooling systems, and basic operations.

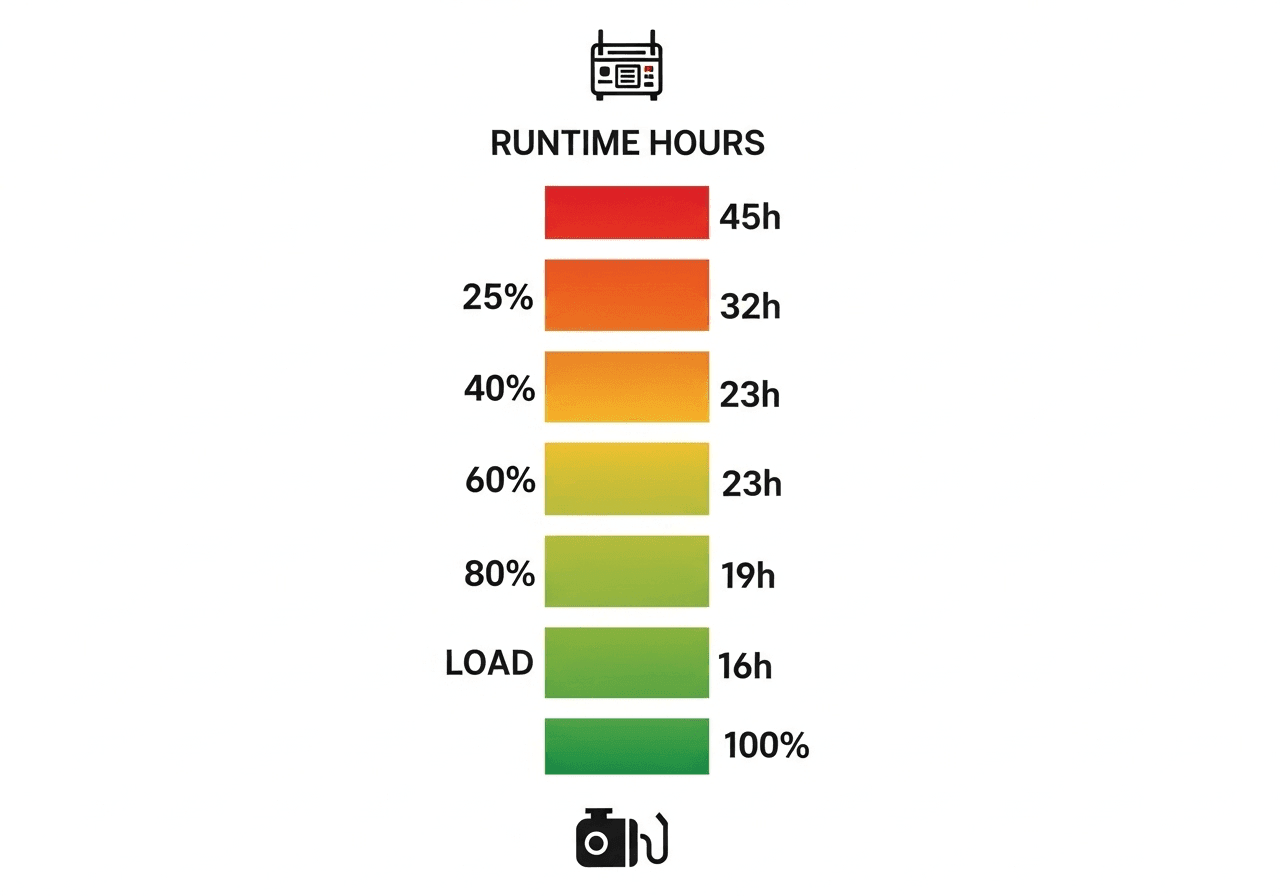

As you add electrical load, fuel consumption scales up, but not linearly. At 25% load, you might use 40% of maximum fuel. At 50% load, about 62%. At 75% load, approximately 81%. Only at 100% load do you hit maximum consumption.

| Load Percentage | Load Factor | Actual Consumption (% of maximum) | Runtime (100L tank, 5 L/h max) | Efficiency Rating |

|---|---|---|---|---|

| 25% | 0.44 | 44% | 40.9 hours | Fair |

| 40% | 0.55 | 55% | 32.7 hours | Good |

| 60% | 0.70 | 70% | 25.7 hours | Excellent |

| 80% | 0.85 | 85% | 21.2 hours | Excellent |

| 100% | 1.00 | 100% | 18.0 hours | Good |

*Example using 100-liter tank at 90% usable capacity (safety reserve), with generator rated at 5 L/h maximum consumption. Note how 60-80% load provides optimal efficiency and runtime balance.

Understanding this curve changes everything. Running your generator at 30% load instead of 80% load doesn't just save a little fuel – it can extend your runtime by 60% or more. For a homeowner during a three-day outage, that's the difference between making it through or running out.

Not all fuels are created equal. Diesel generators are the most efficient, with typical consumption rates of 0.25 to 0.35 liters per kWh produced. Gasoline generators consume about 15% more fuel for the same output. Propane and natural gas generators, while cleaner burning, consume 20-25% more fuel equivalent.

Here's a real example: A 10kW diesel generator running at 50% load typically consumes 1.5 liters per hour. The same load on a gasoline generator? About 1.73 liters per hour. Over a 24-hour outage, that's 5.5 extra liters – potentially the difference between making it through the night and going dark.

| Fuel Type | Consumption Factor | Energy Density (kWh/L) | CO₂ Emissions (kg/L) | Storage Life | Best Application |

|---|---|---|---|---|---|

| Diesel | 1.0x (Baseline) | 10.7 | 2.68 | 6-12 months | Industrial, backup power |

| Gasoline/Petrol | 1.15x (+15%) | 9.7 | 2.31 | 3-6 months | Portable, residential |

| Propane (LPG) | 1.20x (+20%) | 6.9 | 1.51 | Indefinite | Rural, clean burning |

| Natural Gas | 1.25x (+25%) | 10.4 | 2.0 | Continuous supply | Whole-home, continuous |

| HVO (Renewable Diesel) | 1.0x (Same as diesel) | 10.5 | 0.27 (-90%) | 12-24 months | Europe, eco-conscious |

*Consumption factors show relative fuel usage for same power output. Energy density in kilowatt-hours per liter. HVO (Hydrotreated Vegetable Oil) offers diesel performance with dramatically lower emissions.

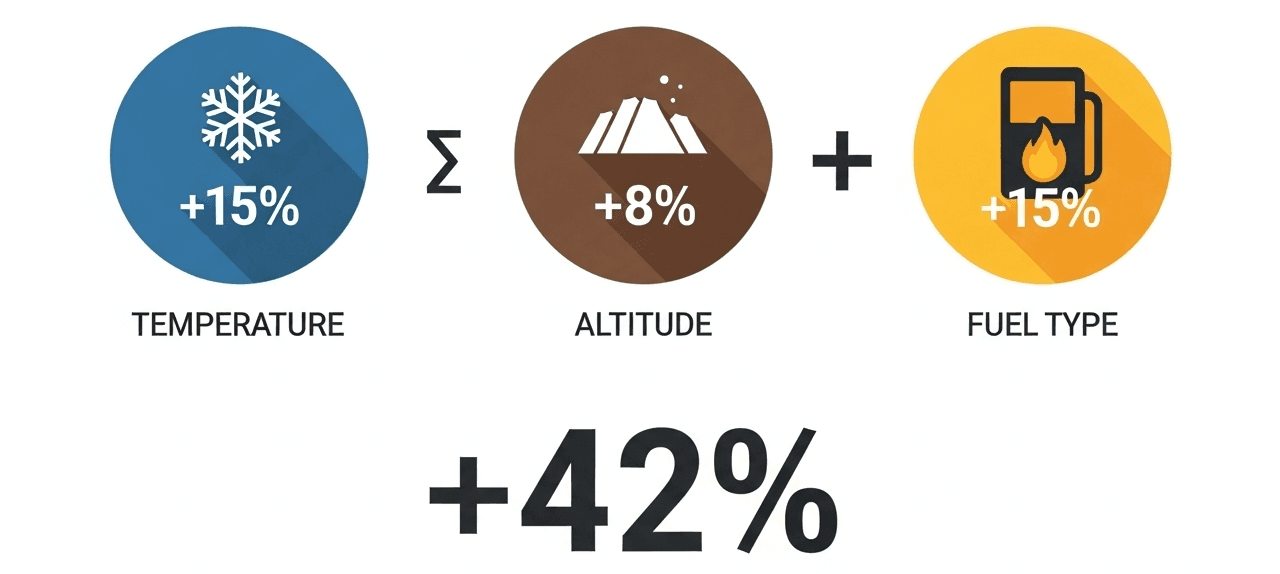

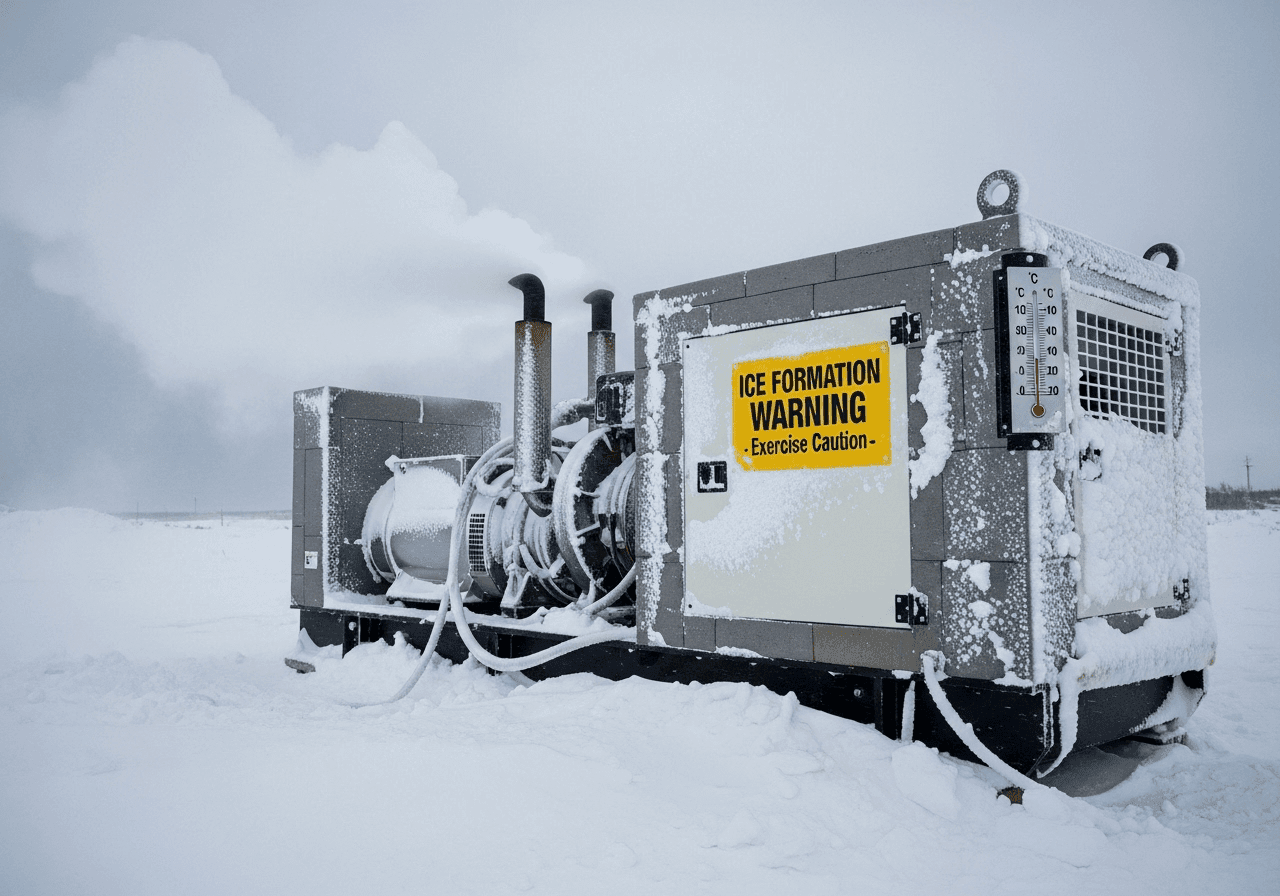

Cold weather kills efficiency. In freezing temperatures, your generator can consume 10-15% more fuel. Why? The engine works harder to maintain operating temperature, fuel doesn't vaporize as efficiently, and increased friction demands more power.

Conversely, extreme heat (above 95°F or 35°C) also increases consumption by about 8-10%. The cooling system works overtime, and hot air is less dense, reducing engine efficiency.

For every 1,000 feet (300 meters) above sea level, your generator loses approximately 3-4% of its power output. To maintain the same electrical output, it must work harder and consume more fuel. A generator in Denver (5,280 feet elevation) consumes roughly 18% more fuel than the same model at sea level in Miami.

This is critical for mountain communities in Colorado, Switzerland, or the Australian highlands. Your manufacturer's consumption specs? They're typically rated at sea level. Without altitude compensation, your runtime calculations could be off by hours.

Now let's get into the meat of it – the actual calculation process that makes these tools so accurate.

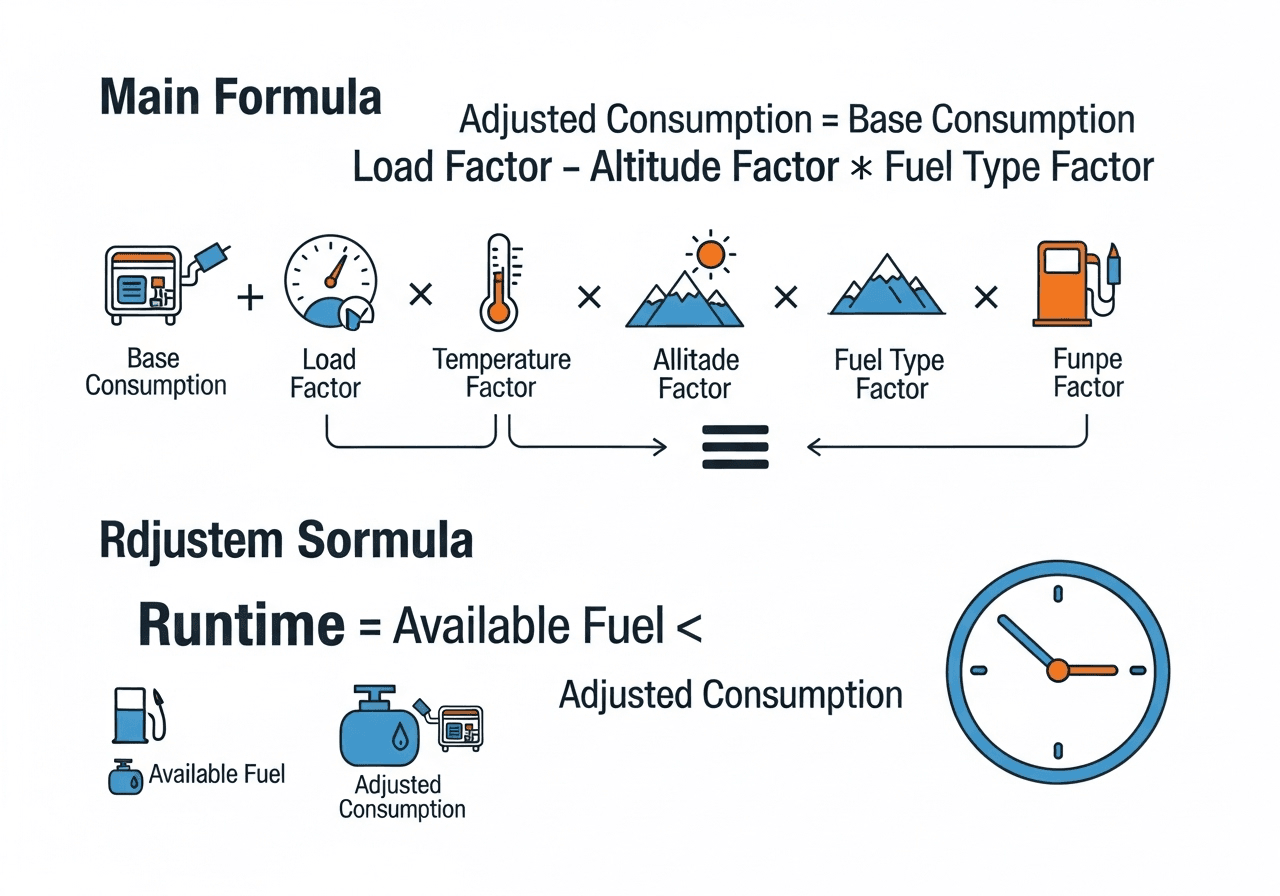

At its heart, the calculation follows this logic:

Adjusted Consumption = Base Consumption × Load Factor × Temperature Factor × Altitude Factor × Fuel Type Factor

Then: Total Runtime (hours) = Available Fuel ÷ Adjusted Consumption

But each of those factors requires careful calculation based on real-world physics and engineering data.

The calculator first establishes your actual load factor using this proven formula:

Load Factor = 0.25 + (Current Load % ÷ 100) × 0.75

This accounts for that 25% base consumption we talked about. So at 60% load: Load Factor = 0.25 + (60 ÷ 100) × 0.75 = 0.25 + 0.45 = 0.70

This means you're consuming 70% of your maximum rated fuel consumption, not 60%.

The calculator adjusts for ambient temperature:

During a Canadian winter at -4°F (-20°C), your generator drinks 15% more fuel. In an Arizona summer at 110°F (43°C), it's 10% more thirsty.

For altitude compensation: Altitude Factor = 1 + (Altitude in meters ÷ 300) × 0.01

Example: At 6,000 feet (1,829 meters) elevation: Altitude Factor = 1 + (1,829 ÷ 300) × 0.01 = 1 + 0.061 = 1.061

Your consumption increases by 6.1%.

Different fuels have different energy densities:

Let's work a real example. You have a generator with:

Load Factor = 0.25 + (60 ÷ 100) × 0.75 = 0.70 Temperature Factor = 1.15 (cold weather) Altitude Factor = 1 + (914 ÷ 300) × 0.01 = 1.030 Fuel Type Factor = 1.0 (diesel)

Adjusted Consumption = 5 × 0.70 × 1.15 × 1.030 × 1.0 = 4.15 L/h

Your tank specs:

Available Fuel = (100 × 0.75) + 50 = 125 liters

However, smart calculators apply a safety reserve of 10% (never run completely dry):

Usable Fuel = 125 × 0.90 = 112.5 liters

Total Runtime = 112.5 ÷ 4.15 = 27.1 hours

That's 27 hours and 6 minutes of runtime under your specific conditions.

Notice how different this is from a naive calculation? If you just took tank size (100L) and divided by rated consumption (5 L/h), you'd get 20 hours. The smart calculator says 27.1 hours – a 35% difference that could make or break your emergency preparedness.

Professional calculators recalculate instantly as conditions change. Temperature drops overnight? Runtime extends slightly. Need to increase load because more family arrived? See immediately how that impacts your fuel timeline.

This dynamic calculation is what separates amateur guessing from professional fuel management.

Using a generator runtime calculator effectively requires understanding what information you need to input. Let's break down each parameter and why it matters.

This is straightforward – how much fuel your generator's primary tank holds when full. However, you need to know the actual capacity, not the manufacturer's rounded number. A "20-gallon" tank might actually hold 19.2 gallons. Check your manual or measure during a controlled fill-up.

For American users, specify gallons (US). Canadians, Europeans, and Australians use liters. Professional calculators auto-convert, but always double-check your units.

You can input this two ways: as a percentage (75%) or absolute volume (75 liters in a 100-liter tank). For accuracy, use a calibrated gauge if available. Visual estimation can be off by 10-15%, which matters when you're calculating for extended outages.

Pro tip: Many generators have inaccurate fuel gauges. Consider installing an aftermarket digital fuel level sensor for precision monitoring, especially for critical applications.

This is your generator's consumption at rated load, typically found in the manufacturer's specifications. Look for "fuel consumption at 100% load" or "maximum fuel consumption rate."

Critical note: Manufacturer specs often reflect ideal conditions (sea level, 77°F/25°C, clean fuel, new engine). Real-world consumption is typically 5-8% higher. If you've operated your generator before, actual measured consumption beats spec sheet numbers every time.

Your generator's maximum output, usually specified in kilowatts (kW) or kilovolt-amperes (kVA). In North America, you'll often see kW. Europe frequently uses kVA.

Quick conversion: kW = kVA × Power Factor (typically 0.8 for resistive loads)

So a 50 kVA generator equals approximately 40 kW of usable power for most applications.

This is where many people struggle. You need to know what percentage of your generator's capacity you're actually using.

If your generator is rated 10 kW and you're running:

Your current load is 2 kW ÷ 10 kW = 20%

Better calculators let you input actual load in kW and auto-calculate the percentage for you.

Alternatively, just list what you're powering. Smart calculators include common appliance databases. Select "refrigerator," "laptop," "space heater," and it totals your load automatically.

This is especially helpful for residential users who aren't engineers. You don't need to know the technical specs – just what you're plugging in.

Input your current outdoor temperature. The calculator compensates for efficiency losses in extreme conditions.

For multi-day outages, use the average expected temperature. If forecasts show a cold front dropping temperatures from 40°F to 10°F (-4°C), plan for the lower temperature to ensure you don't run short.

Enter your location's elevation. Don't know it? A quick online search for "elevation of [your city]" provides this.

Examples:

Choose your specific fuel:

Each fuel has different energy content and consumption characteristics. Getting this right is crucial for accuracy.

Many installations include auxiliary fuel tanks. Input this additional capacity, and the calculator factors it into total runtime. A construction site might have a 50-gallon main tank plus a 100-gallon reserve tank – that's critical for accurate multi-day projections.

Advanced users can input actual measured efficiency (kWh per liter or gallon). This overrides standard calculations with your specific generator's real-world performance.

If you've operated your generator and know it produces 3.2 kWh per liter of diesel (versus the typical 3.5 kWh/L), inputting this custom value dramatically improves accuracy.

For cost tracking, input your local fuel price. The calculator shows you exactly how much you're spending per hour of runtime and total cost for the fuel in your tank. This is invaluable for budgeting and justifying generator upgrades to management.

The calculator is only as good as your inputs. Take five minutes to gather accurate information rather than guessing. Check your manual, measure your fuel level properly, and understand your actual load. These few minutes of preparation can prevent hours or days of problems later.

Once you've input your parameters, the calculator provides a comprehensive dashboard of information. Let's decode what each metric means and how to use it.

This is your headline number – how long your generator will run under current conditions with available fuel. You'll see it displayed prominently in hours and minutes (e.g., "27 hours 15 minutes").

This accounts for all your input variables: load factor, temperature, altitude, fuel type, and the 10% safety reserve. It's not when your tank reads empty – it's when you need to refuel to maintain safe operation.

This countdown tells you exactly when you need more fuel. If it's currently 2 PM and you have 18 hours of runtime, you need to refuel by 8 AM tomorrow morning.

Professional calculators can factor in your fuel supplier's hours. If you know your fuel delivery service closes at 5 PM, the calculator alerts you when you need to order to ensure delivery before they close.

Some advanced calculators show you hour-by-hour fuel remaining. This visualization helps you plan: "At midnight I'll have 60 liters left, at 6 AM about 35 liters, by noon I'll be at reserve levels."

This real-time metric shows exactly how fast you're burning fuel right now, in liters per hour or gallons per hour. As your load changes, this number updates instantly.

Example: You're running essential appliances and seeing 2.3 L/h consumption. You turn on your electric water heater and watch consumption jump to 3.8 L/h. That immediate feedback helps you make informed decisions about what to run and when.

Expressed as kilowatt-hours per liter (kWh/L) or kilowatt-hours per gallon (kWh/gal), this shows how efficiently you're converting fuel to electricity.

Diesel generators typically achieve 3.0 to 3.8 kWh per liter. If your reading shows 2.1 kWh/L, something's wrong – possibly maintenance needed, poor fuel quality, or an efficiency-robbing load (like a damaged appliance drawing excess power).

Different from consumption rate because it factors in your specific load. If you're running at 40% load with 3.5 L/h consumption, but then drop to 25% load, this metric recalculates to show your new consumption rate of approximately 2.8 L/h.

Based on your fuel price input, this shows the total cost of the fuel currently in your system. If you have 125 liters at $1.50 per liter, you're looking at $187.50 in fuel costs.

This number matters for businesses tracking operating expenses and homeowners budgeting for extended outages. During Hurricane Sandy in 2012, New York residents who calculated fuel costs ahead of time saved thousands by refueling strategically when prices were lower.

This metric reveals your actual hourly operating cost. At 4 L/h consumption and $1.50/L, you're spending $6 per hour to run your generator.

Want to reduce costs? Lower your load. Drop from 70% to 45% load, and watch your hourly cost potentially decrease from $8 to $5. Over a three-day outage (72 hours), that's $216 in savings – enough to justify investing in energy-efficient appliances or load management systems.

Professional calculators show your CO₂ output in kilograms. Diesel produces approximately 2.68 kg of CO₂ per liter burned. If you're consuming 4 L/h, you're emitting 10.72 kg of CO₂ hourly, or 257 kg over 24 hours.

In Europe, where carbon reporting is increasingly mandatory, this data helps you file accurate environmental impact reports. In carbon credit markets, it informs offset purchases. For environmentally conscious operators everywhere, it quantifies your footprint.

This normalized metric (kg CO₂ per kWh) lets you compare generator efficiency regardless of size. Lower numbers mean cleaner operation relative to power output.

A well-tuned diesel generator might produce 0.75 kg CO₂ per kWh. A poorly maintained gasoline generator could hit 1.2 kg CO₂ per kWh. This metric identifies when maintenance or upgrades are environmentally justified.

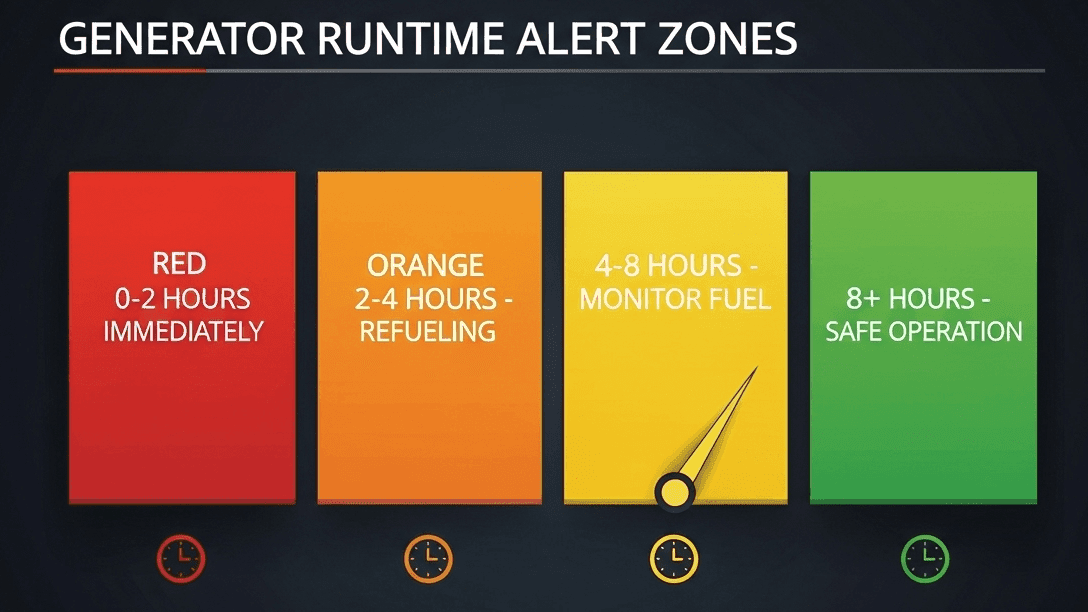

Runtime exceeds 8 hours. You're in good shape. Monitor normally but no immediate action needed. This is your comfort zone for overnight operation without worry.

Runtime between 4-8 hours. Start planning your refueling strategy. Check fuel supplier availability, prepare access for refueling, and consider reducing non-essential loads to extend runtime if needed.

Runtime between 2-4 hours. Action required within the next few hours. Contact your fuel supplier, prepare your refueling station, and alert relevant personnel. This is not panic mode, but procrastination ends here.

Runtime under 2 hours. Critical situation. If you haven't already arranged refueling, you're at risk of outage. Emergency protocols should activate. This is when you're calling the 24-hour fuel delivery emergency line and paying premium rates.

Some calculators show how runtime changes at different load levels. You might see:

This data is gold for optimization. Maybe you can shed 5 kW of load (turning off that inefficient space heater) and gain 7 extra hours of runtime. That calculation could save your operation during an extended outage.

Professional systems recommend exactly when to schedule refueling based on supplier lead times, traffic patterns, and operational criticality. A hospital might get "refuel when 12 hours remain" while a construction site might see "refuel when 6 hours remain."

The best calculators let you save and compare multiple scenarios:

This comparative analysis drives smart investment and operational decisions.

Let's explore how different users leverage generator runtime calculators in real-world scenarios.

Sarah lives in coastal North Carolina. Hurricane warnings just went up for her area, with projected power outages of 3-5 days. She has a 15 kW portable generator with a 7-gallon tank.

Using her runtime calculator, she inputs:

18.5 hours of runtime per tank

For a five-day outage (120 hours), she needs to refuel about 6-7 times. At 7 gallons per fill, that's roughly 45 gallons total. Her local station has fuel available, but she decides to store 30 gallons in approved containers before the storm hits (following all safety regulations).

The calculator just helped her avoid the nightmare scenario of running out of fuel with stations closed due to flooding. She's prepared, confident, and safe.

Tom's father uses a CPAP machine and oxygen concentrator at home. During ice storms, their Texas community loses power for days. His father's life literally depends on backup power.

Tom uses the calculator differently. He inputs his 10 kW generator specs, then calculates backwards:

Required runtime: 72 hours minimum (3 days, the longest historical outage in their area) Critical load: CPAP (80W) + oxygen concentrator (350W) + minimal lighting (100W) = 530W or 5.3% generator load

The calculator shows at 5.3% load, his consumption is only about 0.4 gallons per hour. For 72 hours, he needs 29 gallons. His generator's 8-gallon tank provides 20 hours, meaning he needs to refuel just twice during the three-day period.

But Tom goes further. He adds a 15-gallon external tank to his setup. Now he has 23 gallons total capacity, giving him 57 hours before the first refuel. With one refueling at the 57-hour mark, he clears the 72-hour requirement with fuel to spare.

The calculator transformed his father's critical medical situation from life-threatening to manageable.

A construction company in Vancouver has a major concrete pour scheduled – 150 cubic yards requiring 8 continuous hours of power for pumps, vibrators, and lighting. Stopping mid-pour ruins the concrete and costs $25,000 to $40,000 in removal and replacement.

The site manager uses two 50 kW diesel generators in parallel. He inputs:

With 8 hours needed and 16.8 hours available, he has 100% redundancy. However, he doesn't rely on calculations alone. He stations a 100-gallon fuel truck on-site as backup, scheduled to refuel the generators at the 12-hour mark if the pour runs long.

The calculator gave him confidence to commit to the pour and justified the $800 cost of having the fuel truck standing by. One ruined pour would cost 30 times that amount.

A mining operation in northern Australia runs generators 24/7 to power drilling equipment. Their nearest fuel delivery is 4 hours away by road, longer during wet season when roads flood.

They use sophisticated runtime calculations for fleet management:

Their calculator does more than basic runtime. It predicts:

This advanced fuel management saves them approximately $125,000 annually in fuel costs and prevents the catastrophic scenario of drilling operations halting, which costs $15,000 per hour in lost productivity.

A regional hospital in Germany maintains three natural gas generators for emergency backup, plus diesel generators for critical care units. Their runtime calculations are life-or-death serious.

They input:

Their calculator doesn't just show runtime – it manages a sophisticated switching strategy:

Hours 0-12: Run on natural gas generators (unlimited fuel)

Hours 12-24: If gas supply threatened, switch critical loads to diesel (750 kW at 53% load = 48 hours diesel runtime)

Hours 24+: Diesel generators support critical care only while general operations reduce load or shut down non-essential services

The hospital exceeds regulatory requirements and has documented proof for inspectors. During a 2023 flood that cut natural gas for 36 hours, their calculated fuel management kept all critical systems operational without interruption.

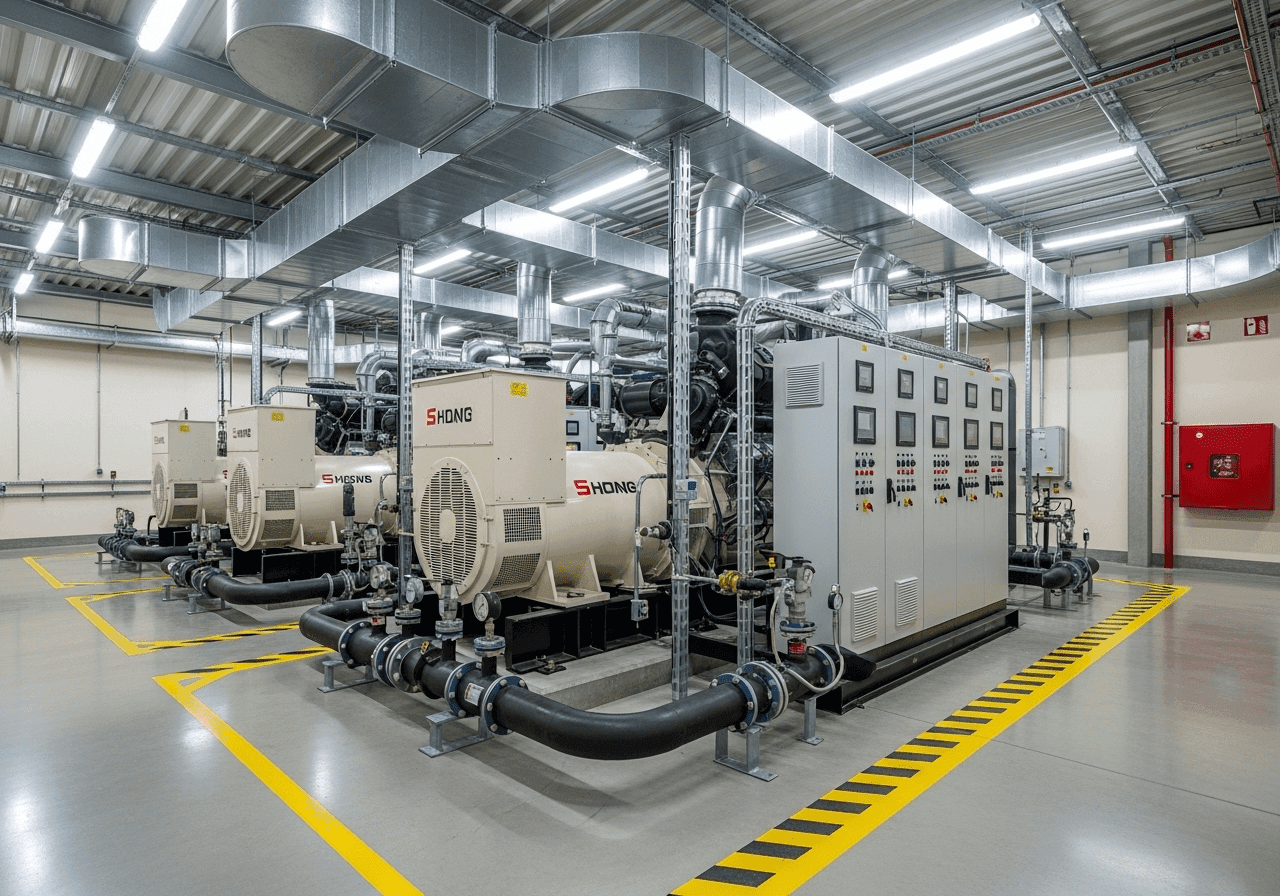

A Tier III data center in Virginia commits to 99.99% uptime – that's less than 53 minutes of downtime allowed per year. Their backup power system is immaculately planned.

They operate:

Using industrial-grade runtime calculators, they monitor:

Their calculator interface integrates with the building management system. When utility power fails, the system automatically calculates whether to run all six generators at 50% load each (most efficient) or four generators at 75% load each (reserve capacity for generator failures).

In 2024, their facility experienced 14 power events. Every single time, their calculated fuel management kept them operational. Clients never noticed an interruption. That's the power of precise runtime prediction.

A music festival in Ontario hosts 50,000 attendees over four days. They need generators for stages, food vendors, medical tents, and lighting. Power failure would be catastrophic – safety issues, legal liability, and reputational damage.

The event coordinator uses runtime calculators to build their power plan:

Main Stage: 200 kW load, two 250 kW generators (redundancy), 200-gallon tanks each Food Court: 150 kW combined, three 75 kW generators, 50-gallon tanks Medical/Safety: 25 kW, one 30 kW generator, 30-gallon tank with backup generator on standby

For the main stage generators at 80% load, the calculator shows 22 hours per tank. With 96 hours of festival operation (4 days), each generator needs 4-5 refuelings. They schedule refueling during set changes when they can temporarily switch to single-generator operation or during lower-draw acoustic sets.

Total fuel calculated: 2,200 gallons for the entire event. They order 2,500 gallons to provide 15% safety margin. The calculator's precision means they neither over-order (expensive waste) nor under-order (potential disaster).

The festival runs flawlessly. Every band plays on time. Every food vendor keeps their refrigerators cold. Every medical device stays powered. That's calculated success.

When floods devastated communities in British Columbia, emergency management teams deployed dozens of generators for shelters, water pumping, emergency lighting, and communications.

Their challenge: limited fuel supplies and roads making delivery difficult. Runtime calculations became critical for triage decisions:

One emergency coordinator reported that runtime calculations "turned chaos into manageable logistics." By knowing exactly when each generator needed refueling and how much fuel that required, they could prioritize fuel truck deployments.

A shelter with 18 hours of runtime left could wait while a water pumping station with 4 hours got immediate refueling. Lives were saved through intelligent fuel allocation, all based on accurate runtime calculations.

Generator runtime calculations aren't one-size-fits-all. Different regions face unique challenges requiring specialized approaches.

North America sees some of the world's most severe weather variations. A generator in International Falls, Minnesota, operates in -40°F winters, while one in Phoenix, Arizona, endures 120°F summers. Both extremes dramatically impact runtime.

Canadian operators deal with fuel gelling. Diesel fuel starts forming wax crystals at 14°F (-10°C), potentially clogging fuel lines. Winter blend diesel and additives help, but cold weather still increases consumption by 10-15%.

Smart calculators for Canadian markets include winter operation modes that factor in block heater consumption (typically 400-1500W), increased cranking power needs, and extended warm-up periods. A generator in Winnipeg during January requires 20-30 minutes of warm-up before accepting full load, consuming fuel without productive output.

Coastal regions from Florida to the Carolinas and Gulf Coast states face hurricane seasons with multi-day power outages. Runtime calculators here emphasize extended operation scenarios – 5 to 14 days without grid power.

The 2021 Texas ice storm demonstrated another critical need. Millions lost power for up to 10 days in freezing conditions. Texans with generators ran heating equipment continuously, creating high-load scenarios that drained fuel faster than expected. Those who used runtime calculators to plan fuel storage survived comfortably; those who didn't faced dangerous situations.

The US and Canada predominantly use ULSD (Ultra Low Sulfur Diesel) since 2010, which has slightly lower energy content than older high-sulfur diesel. Modern calculators account for this 2-3% efficiency reduction.

| Region | Fuel Volume Unit | Consumption Unit | Power Unit | Temperature Unit | Primary Fuel Standard |

|---|---|---|---|---|---|

| USA | Gallons (US) | GPH | kW / HP | °F | ULSD (EPA Tier 4) |

| Canada | Liters | L/h | kW | °C | ULSD (CSA Standards) |

| Europe (EU) | Litres | L/h | kW / kVA | °C | EN 590 (Stage V) |

| UK | Litres | L/h | kW | °C | BS 2869 |

| Australia | Litres | L/h | kW | °C | AS 3570 |

Gasoline options vary by region. California requires special reformulated gasoline (RFG) that burns cleaner but provides slightly less energy per gallon. Altitude matters too – mountain states sell gasoline blended for higher elevations, affecting generator performance differently than sea-level formulations.

EPA Tier 4 emissions standards in the US require specific calculations for commercial operations. Companies must document runtime, fuel consumption, and emissions for environmental reporting. Professional calculators generate these reports automatically.

In Canada, provincial regulations vary. Ontario requires specific emissions documentation for generators over 500 kW. British Columbia has strict noise bylaws affecting urban generator operation. Quebec mandates bilingual safety documentation.

North American fuel prices vary dramatically by region. As of 2025, diesel ranges from $2.80/gallon in Texas to $5.20/gallon in California. This 85% price difference makes cost-per-hour calculations essential for budgeting.

Canadian prices hover around CAD $1.70-$2.10 per liter for diesel, with significant provincial tax variations. Atlantic Canada pays more due to transportation costs. Alberta typically enjoys lower prices due to proximity to oil production.

Europe leads the world in environmental regulations. EU Stage V emissions standards are the strictest globally, requiring sophisticated exhaust treatment systems that slightly increase fuel consumption.

Runtime calculators for European markets must track and report emissions in formats compatible with national environmental agencies. Germany's Umweltbundesamt, France's ADEME, and UK's Environment Agency each have specific reporting requirements.

Many European nations implement carbon pricing or taxes. In Sweden, carbon tax adds approximately €110 per ton of CO₂ emissions. For a generator producing 500 kg of CO₂ over a weekend (running at 25 kW for 48 hours), that's €55 in carbon costs on top of fuel expenses.

Smart calculators in European markets include carbon cost calculations and offset purchasing recommendations. Some integrate directly with carbon credit marketplaces.

European cities enforce strict noise ordinances. Residential generators typically cannot exceed 65 dB(A) during daytime and 55 dB(A) at night. Many jurisdictions prohibit generator operation between 10 PM and 7 AM except in emergencies.

Runtime calculators for Europe include noise compliance features. If your operation requires 24-hour runtime but local laws prohibit nighttime operation, the calculator helps you design battery storage systems to bridge the quiet hours or plan load reduction strategies.

Europe embraces HVO (Hydrotreated Vegetable Oil), a renewable diesel replacement. HVO provides nearly identical energy content to petroleum diesel but with 90% lower carbon emissions. Advanced calculators offer HVO as a fuel option with appropriate emissions calculations.

Biodiesel blends (B7, B20, B30) are common across Europe. Each blend has different energy content requiring specific consumption calculations. A B20 blend contains 20% biodiesel and 80% petroleum diesel, reducing energy content by approximately 2% compared to pure diesel.

Agricultural and certain industrial operations in Europe can use red diesel (marked gas oil), which is taxed much lower than road diesel. UK red diesel costs roughly 30% less than standard diesel.

However, red diesel usage is restricted and heavily monitored. Calculators help operations determine if red diesel eligibility justifies the regulatory compliance overhead for their usage patterns.

A logistics company operating warehouses across Germany, France, and Poland faces different regulations in each country. Their generator runtime system must accommodate:

Professional calculators offer multi-country compliance profiles, automatically generating required documentation for each jurisdiction.

Northern Europe (Scandinavia, Germany, Netherlands) enjoys extremely reliable grid power. Generator usage here is primarily planned maintenance windows or precautionary backup during storms.

Southern and Eastern Europe experience more frequent outages. Greece, parts of Italy, and some Eastern European nations face occasional grid instability, making runtime calculations more critical for business continuity.

Post-Brexit, the UK maintains unique requirements. British Standards (BS 7698, BS 7671) govern generator installations and safety. Scottish regulations differ slightly from English ones, particularly regarding environmental protection near water sources.

UK operators deal with unpredictable weather – sudden cold snaps, flooding, and wind events. Runtime calculators help British users plan for rapid weather changes that affect both fuel consumption and operational necessity.

Australia's inland regions experience brutal conditions. Summer temperatures regularly exceed 113°F (45°C) in central and northern areas. At these extremes, generators lose 12-15% efficiency.

Dust is equally problematic. The Outback's fine red dust clogs air filters rapidly, reducing efficiency and increasing fuel consumption. Australian-focused calculators include dust factor adjustments and maintenance interval tracking tied to runtime in dusty conditions.

Australia's vast distances create unique challenges. A mining operation in the Pilbara region might be 800 kilometers from the nearest major fuel supplier. Fuel logistics planning becomes critical – one miscalculation could mean a $50,000 helicopter fuel delivery.

Remote stations often maintain enormous fuel reserves – 5,000 to 10,000 liters. Runtime calculators for Australian remote operations emphasize long-term fuel management, accounting for evaporation losses in heat (up to 2% monthly) and planning delivery schedules months in advance.

Bushfire season creates unique power needs. Residents in fire-prone areas use generators for water pumps (fire defense), refrigeration (food preservation during evacuations), and communications (emergency contact).

Australian runtime calculators include bushfire scenario planning. Users input their Critical Fire Danger days count (typically 20-40 days per season) and the calculator helps them stockpile appropriate fuel reserves while complying with safe storage regulations.

Australia leads the world in residential solar adoption. Many Australian homes integrate generators with solar systems for ultimate resilience. Runtime calculators account for solar contribution, showing how daytime solar generation can dramatically extend generator fuel by reducing generator load to nighttime-only operation.

Example: A home in rural Queensland with 8 kW solar and a 10 kW diesel generator can run entirely on solar during day (8 AM to 5 PM), then switch to generator for 13 hours overnight. This hybrid approach might extend a 200-liter fuel supply from 40 hours (generator-only) to 120+ hours (solar-assisted).

Many Aboriginal communities rely entirely on diesel generators for electricity. Fuel costs represent major expenses – sometimes 30-40% of total operating budgets.

Runtime calculators help these communities optimize consumption, schedule maintenance to prevent inefficient operation, and justify government funding requests with detailed fuel consumption documentation. Reducing fuel consumption by even 10% through better load management can save tens of thousands annually.

Australia's coastal geography means many island communities and marine facilities depend on generators. Salt air accelerates corrosion and equipment degradation, increasing fuel consumption over time.

Island calculators factor in marine environment deterioration rates, recommending more frequent efficiency testing and maintenance schedules. They also account for fuel delivery challenges – ferries that only run twice weekly or weather windows that limit boat access.

Australian mining operations consume massive amounts of generator power. A large site might burn 20,000 liters of diesel daily across multiple generators.

Mining-grade runtime calculators integrate with SCADA (Supervisory Control and Data Acquisition) systems, automatically logging fuel consumption, calculating costs, and generating environmental compliance reports required by state mining regulators.

Australian states have varying requirements. Western Australia's Department of Water and Environmental Regulation requires emissions reporting for generators over 300 kW. Queensland's Environmental Protection Act mandates specific operating hours restrictions near residential areas.

Professional calculators include Australian state-specific compliance modules, automatically adjusting calculations and reports to match the relevant jurisdiction's requirements.

Australia spans tropical (Darwin), desert (Alice Springs), temperate (Melbourne), to cool oceanic (Tasmania). A single nationwide calculation approach doesn't work.

Smart calculators use location-based weather data. Input "Darwin" and it assumes high heat and humidity year-round. Input "Hobart" and it plans for milder temperatures but more rainfall and wind, which affects outdoor generator operation.

Beyond basic runtime calculations, professional-grade tools provide features that transform generator management from reactive to proactive.

Large facilities rarely rely on single generators. Professional calculators manage generator fleets with sophisticated algorithms.

When running multiple generators in parallel, load distribution affects efficiency. Two 100 kW generators running at 40% load each (80 kW total) consume more fuel than one generator at 80% load plus one on standby.

Professional calculators analyze your load profile and recommend optimal generator combinations. Should you run two units at 60% each or three units at 40% each? The calculator shows fuel consumption, wear-and-tear implications, and cost differences for each scenario.

When one generator nears empty, when should you switch to the backup? Too early wastes fuel capacity. Too late risks interruption during the changeover.

Smart calculators recommend switchover timing based on:

A hospital might switch when 60 minutes remain on the primary. A construction site might wait until 15 minutes remain. The calculator customizes recommendations to your risk tolerance.

Industrial sites with 4-10 generators face complex optimization challenges. Which units run, which stay on standby, and when do you rotate to distribute wear evenly?

Professional systems use algorithms that consider:

One Australian mining operation reduced fuel consumption by 8% simply by using calculator-driven generator rotation instead of manual "whoever starts easiest" selection.

The most advanced calculators don't just calculate – they learn and predict.

After operating for several weeks, AI-powered calculators identify your typical usage patterns:

Armed with this knowledge, the calculator predicts future fuel needs with remarkable accuracy. Instead of just showing current runtime, it forecasts: "Based on historical patterns, you'll need refueling Tuesday afternoon."

Fuel efficiency degrades as generators age and components wear. Smart calculators track efficiency over time, alerting you when consumption increases beyond normal ranges.

If your generator historically consumed 4.2 L/h at 60% load but now consumes 4.8 L/h at the same load, something's wrong. Possible causes include dirty air filters, injector problems, or declining engine health. Early detection prevents small issues from becoming expensive failures.

Advanced systems integrate with weather services, automatically adjusting predictions based on forecasts.

When a cold front is predicted to arrive Tuesday evening, the calculator updates runtime estimates to reflect the 10-15% consumption increase you'll experience in colder temperatures. You get proactive alerts: "Weather change will reduce runtime by 4 hours. Consider refueling Monday instead of Wednesday."

This feature proved invaluable during the 2024 North American winter storms, when users received 48-hour advance warnings that plunging temperatures would significantly impact their fuel reserves.

Professional calculators excel at answering "what if" questions.

What if you shed 5 kW of non-essential load? The calculator instantly shows runtime extension. Maybe that 23 hours becomes 31 hours – enough to make it through the night without refueling.

You can test multiple scenarios:

This analysis helps you make informed decisions during emergencies. Which loads can you sacrifice to extend runtime? The calculator quantifies the trade-offs.

How much runtime do you gain by adding external fuel? Input a 50-gallon auxiliary tank and immediately see your runtime jump from 16 hours to 38 hours.

This justifies investment decisions. If a $400 auxiliary tank setup gives you 22 additional hours of runtime during outages, and avoiding even one spoiled freezer load saves $600, the ROI is immediate.

Many modern generators offer eco modes that throttle down during light loads. Professional calculators compare modes:

Standard Mode: Full RPM always, 18 hours runtime

Eco Mode: Variable RPM based on load, 24 hours runtime, but 2-second delay during sudden load increases

Is the 33% runtime extension worth the slight response delay? For most applications, yes. For surgical equipment or data centers, maybe not. The calculator helps you make informed operational choices.

Some industrial operations have access to time-variable fuel pricing (cheaper delivery during off-peak hours). Calculators with cost optimization schedule refueling for minimum cost windows.

If Monday morning delivery costs $3.20/gallon but Wednesday afternoon delivery costs $2.85/gallon, and your runtime shows you can wait until Wednesday, the calculator recommends the later delivery, potentially saving hundreds of dollars per refueling.

Should you order fuel in smaller regular deliveries or bulk shipments with storage? The calculator analyzes:

For a business consuming 500 gallons monthly, the calculator might show that a 1,000-gallon storage tank with quarterly bulk deliveries saves $3,200 annually after factoring all costs.

If you're purchasing a new generator, the calculator analyzes your load profiles and recommends optimal sizing.

Running a 100 kW generator at constant 30% load is inefficient – fuel consumption per kWh produced is poor. The calculator might recommend: "A 50 kW generator at 60% load would reduce your fuel consumption by 18% for the same output."

This analysis has saved industrial purchasers tens of thousands by preventing over-sizing (common in the industry due to "better safe than sorry" mentality).

Professional operations require documentation. Advanced calculators generate comprehensive reports.

Runtime tracking integrated with maintenance schedules. When your generator hits 500 hours (typical oil change interval), you receive alerts with automatic service reports showing operating conditions during those hours.

These logs prove invaluable for warranty claims. If a generator fails prematurely, documented evidence of proper operation and maintenance, including fuel consumption patterns that indicate responsible use, strengthens warranty positions.

Automated generation of emissions reports in formats required by regulatory agencies. For European operations, this might be monthly CO₂ reports. For US facilities, quarterly EPA submissions. For Canadian operations, provincial environmental office documentation.

One facility manager in Germany reported saving 40 hours annually (worth €2,000+ in labor costs) by eliminating manual emissions report compilation.

Detailed cost tracking exportable to accounting systems. Reports show:

These reports justify generator operation costs to management and help businesses accurately bid contracts that include generator operation.

Long-term data collection enables year-over-year comparisons. You can identify trends like:

This intelligence transforms generators from "necessary equipment" to "optimized assets" with measurable performance metrics.

Even with sophisticated calculators, users make predictable mistakes. Let's identify and prevent them.

Manufacturer fuel consumption specs assume perfect conditions: new engine, clean fuel, proper maintenance, ideal temperature, sea level operation. Real-world consumption is typically 5-15% higher.

After your first few operating sessions, measure actual consumption. Run your generator at known loads for measured time periods and calculate true consumption rates. Update your calculator inputs with these real numbers.

One construction company discovered their "5 L/h rated" generator actually consumed 5.8 L/h under their typical conditions. That 16% difference meant their runtime calculations were consistently 14% too optimistic – a potentially dangerous error.

Not all loads are equal. Resistive loads (heaters, incandescent lights) have power factors near 1.0. Inductive loads (motors, compressors) have power factors of 0.6-0.8, meaning they draw more current for the same wattage.

A 5 kW motor with 0.7 power factor draws 7.1 kVA from your generator. If your generator is rated in kW but you're running mostly inductive loads, you might overload it while thinking you're at safe levels.

Know your load types. When inputting loads into calculators, specify whether they're resistive or inductive. Better calculators include power factor adjustments. If your generator is rated in kVA, convert to kW by multiplying by your average power factor (typically 0.8 for mixed loads).

Electric motors draw 3-7 times their running current during startup. Your refrigerator runs at 800W but draws 4,000W for 2-3 seconds when the compressor starts.

Users often calculate total running load without accounting for surge. Everything runs fine until the well pump starts, causing a massive surge that either overloads the generator or causes voltage drop that damages sensitive electronics.

Professional calculators include surge consideration features. Input your motor loads and the calculator factors in surge capacity requirements. Alternatively, follow the rule of thumb: maintain 30% capacity headroom beyond steady-state load to handle surges.

For critical applications, use soft-start devices on large motors to eliminate surge issues entirely.

Running a generator at under 30% load for extended periods causes "wet stacking" in diesel generators – unburned fuel accumulates in the exhaust system, reducing efficiency and potentially damaging the engine.

Users calculate runtime at 15% load and think they're maximizing fuel efficiency. Actually, they're creating maintenance problems and reducing actual efficiency due to incomplete combustion.

Maintain loads above 30% of generator capacity when possible. If your typical load is only 20%, consider a smaller generator. If load varies, schedule periodic high-load exercises (monthly operation at 60-70% load for 30 minutes) to burn off accumulated deposits.

Advanced calculators include wet stacking warnings when you operate below recommended load thresholds for extended periods.

Diesel fuel degrades within 6-12 months, especially in warm climates. Degraded fuel reduces energy content and can clog fuel systems. Gasoline degrades even faster – 3-6 months without stabilizers.

Users store fuel for "emergency readiness," then discover during an actual emergency that their calculated 48-hour runtime is actually 38 hours because their year-old fuel has lost 20% of its energy content.

Date your fuel storage. Use fuel stabilizers appropriate to your fuel type. Rotate stored fuel (use and replace) every 3-4 months for gasoline, 6-8 months for diesel in warm climates, 10-12 months for diesel in cool climates.

Professional calculators can track fuel age and provide degradation estimates. Input your fuel storage date and the calculator reduces expected runtime accordingly.

Users at elevation forget that their generator produces less power at altitude. A 50 kW generator at 6,000 feet produces only about 42 kW. If you calculate based on 50 kW capacity and try to run 45 kW of load, you'll overload your generator.

This mistake is common among users who purchase generators at sea-level locations then transport them to mountain properties. Their capacity assumptions are dangerously incorrect.

Always input your actual operating altitude. If you move your generator to different elevations seasonally (mountain cabin in summer, sea-level home in winter), recalculate for each location.

Consider generators with turbochargers or superchargers that maintain power output at altitude, though they cost 30-40% more than naturally aspirated models.

Calculators typically recommend maintaining 10% fuel reserve – never running below this level. In reality, during emergencies, users often violate this rule, running tanks nearly dry.

Running a generator on fumes draws sediment and contaminants into the fuel system, potentially causing injector damage that costs $1,500-$3,000 to repair. Yet users repeatedly make this mistake during desperation situations.

Treat the calculated reserve as absolute, not suggested. Program alarms on your generator (if capable) to shut down at 10% fuel rather than at empty. The momentary interruption during refueling is far better than the catastrophic interruption of a contaminated fuel system.

If your situation is truly critical, maintain 20% reserve instead of 10% to provide additional safety margin during chaotic emergency conditions when judgment may be impaired.

Users calculate runtime for their primary fuel source without considering "what if" scenarios. What if your fuel delivery is delayed? What if your stored fuel is contaminated? What if you miscalculated?

Relying entirely on calculation accuracy without backup plans is risky. Murphy's Law applies especially to emergencies – if something can go wrong, it will.

Use calculator scenarios to plan redundancy. If calculations show 48 hours runtime, plan for at least one intermediate refueling at 24 hours even if theoretically unnecessary. Stock 20-30% more fuel than calculations suggest you need.

Have backup suppliers identified. Know multiple fuel sources in your area. Maintain relationships with emergency fuel delivery services even if you never use them.

Users might account for temperature OR altitude OR fuel type, but forget these factors multiply rather than add. A 10% temperature penalty plus an 8% altitude penalty doesn't equal 18% – it's 1.10 × 1.08 = 1.188 or 18.8% when factors multiply.

Missing this multiplication effect causes runtime estimates to be optimistic by several percentage points, which compounds over long outages into hours of missing runtime.

Use professional calculators that apply multiplicative factors correctly. Don't try to manually adjust for multiple variables – the math gets complex quickly. Trust the calculator's sophisticated algorithms.

Verify your understanding by testing calculated predictions against real-world operation, then adjust your inputs if systematic discrepancies appear.

Users calculate runtime at their initial load, then add equipment throughout the outage without recalculating. They start at 40% load (good efficiency, long runtime), then progressively add loads until they're at 85% load (poor efficiency, high consumption), wondering why they're running out of fuel faster than expected.

Recalculate every time you significantly change your load – more than 10-15% up or down. Professional calculators make this easy with real-time updates. Get in the habit of checking the calculator after adding or removing major loads.

For planned operations, pre-calculate multiple scenarios with different load profiles so you understand the impact before making changes during actual operation.

Getting accurate calculations is one thing – optimizing your generator for maximum efficiency is another. Here's how to ensure your generator delivers the runtime your calculations predict.

Dirty oil increases friction, reducing engine efficiency by 5-10%. Follow manufacturer intervals religiously – typically every 100-200 hours for most generators, or annually if runtime is low.

Synthetic oils maintain viscosity better in temperature extremes, potentially improving efficiency by 2-3% compared to conventional oils. For generators operating in harsh conditions, the extra cost pays for itself in fuel savings and extended engine life.

A clogged air filter restricts airflow, causing incomplete combustion and fuel waste. In dusty environments like construction sites or rural areas, check filters every 25 hours of operation. Clean or replace as needed.

One mining operation in Western Australia implemented weekly filter inspections and reduced fuel consumption by 7% simply by maintaining clean air supply. That translated to $18,000 annual savings on a large generator.

Water and contaminants in fuel reduce combustion efficiency and can cause engine damage. Use fuel filters rated for your application. For critical operations, install fuel/water separators.

Drain fuel tank condensation weekly in humid climates. Water accumulates at the bottom of tanks, especially during temperature cycling. Those few minutes of maintenance prevent efficiency losses and expensive repairs.

Generators achieve peak fuel efficiency at 60-80% of rated capacity. Running at 30% wastes fuel through incomplete combustion. Running at 95%+ stresses components and slightly reduces efficiency.

Use your calculator's scenario features to identify the sweet spot. If you need 15 kW of power, a 20 kW generator at 75% load is more efficient than a 30 kW generator at 50% load, despite both handling the load comfortably.

Establish clear priorities for which loads to shed first when extending runtime becomes critical. Professional calculators help you quantify the impact:

During extended outages, systematically shed Tier 3 loads first. Your calculator shows exactly how many hours of runtime you gain. Maybe disconnecting that 1,500W space heater extends runtime by 8 hours – potentially making the difference between comfort and crisis.

Don't start everything simultaneously. Sequence motor startups with 30-60 second gaps. This prevents multiple surge currents overlapping, reduces stress on your generator, and maintains stable voltage.

Unstable voltage from overloading surges reduces efficiency and can damage sensitive electronics. Proper sequencing, easily planned using calculator load analysis, eliminates these issues.

Premium diesel with higher cetane ratings (45-50 vs. 40-42 standard) burns more efficiently, potentially improving fuel economy by 3-5%. For operations burning thousands of gallons annually, this efficiency gain offsets the premium fuel cost.

Ultra-low sulfur diesel (ULSD), while environmentally mandated in most developed countries, has slightly lower energy content than older formulations. If your generator's specifications were written before 2010, adjust your consumption expectations upward by 2-3%.

Quality fuel additives provide multiple benefits:

For a 100-liter fill, premium additive treatment costs $3-5 but can improve efficiency enough to pay for itself in fuel savings while preventing maintenance issues.

Store fuel in cool, dark locations. Heat accelerates degradation. A fuel storage tank in direct Arizona sun reaches 140°F+ internally, degrading diesel 3-4 times faster than shaded storage at 80°F.

Use opaque containers or tanks. UV light degrades fuel. If you must use translucent containers, store them in complete darkness.

Generators lose efficiency in temperature extremes. You can't control weather, but you can control generator environment:

Cold Weather: Use block heaters to maintain engine temperature. A warm engine starts easier and reaches operating efficiency faster. Insulated generator enclosures maintain temperature, reducing cold-start fuel consumption by 15-20%.

Hot Weather: Ensure adequate ventilation. An overheating generator reduces output and increases fuel consumption while working to cool itself. Shade your generator. Direct sun exposure can increase surface temperatures by 30-40°F, affecting cooling system efficiency.

You can't change altitude, but understanding its effects helps you optimize. At high elevations:

High humidity slightly reduces combustion efficiency (1-2%). More significantly, humidity accelerates fuel tank condensation and rust. In tropical or coastal areas, use corrosion-inhibiting fuel additives and drain condensation weekly.

If purchasing new or upgrading old equipment, EFI (Electronic Fuel Injection) generators consume 15-25% less fuel than carbureted models. The precision fuel metering optimizes combustion across all load ranges.

The fuel savings often recoup the 20-30% higher purchase price within 2-3 years of regular use.

AVR systems maintain stable voltage output without engine speed variations, improving efficiency. Older generator models vary engine speed (and fuel consumption) to regulate voltage. AVR-equipped units maintain constant optimal RPM, reducing fuel waste.

Install remote monitoring for real-time efficiency tracking. Systems costing $200-500 provide:

One commercial facility identified a failing compressor drawing 40% excess power through monitoring alerts. Repairing the compressor ($800 cost) reduced generator load by 3 kW, saving approximately $2,400 annually in fuel costs.

The biggest efficiency mistake is poor generator sizing. An oversized generator running at 20-30% load constantly is profoundly inefficient.

If your typical load is 12 kW, a 15-18 kW generator operating at 65-80% load is optimal. A 30 kW generator running at 40% wastes fuel and causes maintenance problems.

Use calculator historical data to identify your actual usage patterns over weeks or months. You might discover your "necessary" 50 kW generator rarely exceeds 30 kW load. Switching to a properly-sized unit (with the oversized unit as backup) could reduce fuel consumption by 20-30%.

Two smaller generators in parallel often outperform one large unit. Run one generator at optimal 70% load during normal operations. When load increases, start the second. When load decreases, shut down one unit.

This flexible configuration maintains high efficiency across varying loads. The calculator helps you determine optimal parallel operation strategies for your specific load profile.

Not all calculators are created equal. Here's what to look for when selecting a tool for your needs.

Free online calculators like those offered by major generator manufacturers (Generac, Honda, Champion) provide adequate functionality for occasional residential use. They're simple, accessible, and sufficient for basic planning.

For frequent users or those in outage-prone areas, dedicated apps ($5-15) offer enhanced features like historical tracking, multiple generator profiles, and offline operation.

Professional software packages ($50-200 annually) like Genset Manager, PowerPlan Pro, or FuelTrack Commercial provide comprehensive features. These tools typically offer:

For small businesses, the investment pays for itself quickly. One restaurant owner in Toronto reported that proper fuel management through professional software saved $3,200 annually by preventing over-ordering fuel and optimizing generator run schedules during planned maintenance windows.

Enterprise-grade platforms ($500-5,000+ annually) like AssetLink, Industrial Power Manager, or custom-developed solutions provide mission-critical reliability. These systems offer:

For critical facilities (hospitals, data centers, emergency services), these sophisticated systems aren't optional – they're essential infrastructure. The cost is negligible compared to the consequences of power failure.

Test the calculator against known scenarios. Input specifications from generators you've operated and compare calculated runtime to actual measured runtime. Quality calculators should predict within 5-10% of reality.

Beware of calculators using overly simplified formulas (just tank size ÷ consumption rate). These ignore load factors, environmental conditions, and fuel type differences, producing estimates that can be 20-40% inaccurate.

For commercial applications, understand where your data is stored. Cloud-based systems offer convenience but require trust in the provider's security. Look for:

Some industries (defense, healthcare, finance) may require on-premises solutions rather than cloud storage due to regulatory requirements.

The best calculator balances power and simplicity. You need advanced features but don't want 30 minutes of setup for each calculation.

Look for:

Modern calculators should work seamlessly across devices. You might configure detailed scenarios on your desktop but need quick runtime checks on your phone during an outage.

Ensure the calculator offers:

Technology evolves. Fuel standards change. New generator models emerge. Your calculator should receive regular updates.

Check:

Free calculators work for occasional use, but serious operations need professional tools. Consider the ROI:

If a $200/year calculator prevents one instance of running out of fuel (potentially costing $5,000 in downtime, emergency delivery fees, and lost productivity), it pays for itself 25 times over.

For industrial operations, if the calculator optimizes fuel consumption by even 3% through better load management, the savings on fuel costs alone justify significant investment in sophisticated tools.

Reputable calculator providers offer:

Never commit to expensive professional software without thorough testing against your actual generators and operational scenarios.

You've journeyed through the complete landscape of generator runtime calculation – from basic principles to professional-grade fleet management. Now you understand that accurate runtime prediction isn't just mathematics; it's about safety, financial efficiency, and peace of mind.

The difference between guessing and knowing your generator runtime can literally save lives during medical emergencies, prevent hundreds of thousands in industrial downtime, and protect families during extended outages. Whether you're a homeowner preparing for storm season, a business manager maintaining operations, or an industrial engineer overseeing critical systems, precision fuel management transforms your generator from a backup tool into a strategic asset.

Smart runtime calculators do more than predict numbers – they empower intelligent decisions. Should you refuel now or wait three hours? Can you run that additional equipment without compromising your safety margin? Will your current fuel supply last through the night? These questions, which once required educated guesses, now have precise answers.

Remember the fundamentals: accurate inputs produce reliable outputs, environmental factors multiply rather than add, and real-world testing beats manufacturer specifications. Invest in appropriate tools for your application – basic free calculators suffice for occasional residential use, while critical commercial operations demand professional systems with comprehensive features.

Start implementing what you've learned today. Download a quality calculator, input your generator specifications, and run scenarios. Test predictions against actual operation. Build confidence in your fuel management capabilities before emergencies strike, not during them.

The next power outage is inevitable. The question isn't whether you'll need your generator – it's whether you'll know exactly how long it will run. Now you have the knowledge to answer that question with confidence.

Calculate your generator runtime, verify your fuel reserves, and establish monitoring practices. Your future self, facing the next outage with complete confidence instead of anxious uncertainty, will thank you.

Never guess again. Calculate, plan, and stay powered.

Direct links to the primary pages and documents you requested (EPA, EU Stage V, NRCan, AS / Standards Australia, NFPA 110, Engine/Diesel forum, EGSA, ISO 8528, CSA, UK HSE).